Why 85% of Food Safety Risks are within your Easy Control

According to recent studies, up to 85% of food safety incidents stem from errors in these critical controls.

This includes everything from improper temperatures during transportation to undercooked food that allows pathogens to thrive.

Why does this matter so much?

In the intricate food service ecosystem, even minor oversights can trigger devastating consequences: foodborne illnesses, fines, loss of customer trust, and long-term reputational damage.

In this article, we break down why 85% of food safety risks are in your hands, and more importantly, how to mitigate them effectively.

The critical importance of Time and Temperature Control

Managing time and temperature is not just a theoretical recommendation or a “nice-to-have” in a professional kitchen.

It is the most effective barrier against food safety risks.

When neglected, the consequences can be disastrous—for public health, business reputation, and financial performance.

Why is this so crucial?

1/ Microbial Growth

Pathogens such as Salmonella, Listeria monocytogenes, and E. coli O157:H7 thrive in the so-called “danger zone” between 4°C and 60°C.

-

- According to the FDA, bacteria can double in number every 20 minutes under these conditions.

- A mere two-hour lapse can turn safe food into a serious health hazard.

2/ Beyond Safety: Quality and Freshness

It’s not just about preventing illnesses. Foods exposed to improper temperatures lose texture, flavor, and nutritional value, which negatively affects customer satisfaction and increases waste.

3/ Mandatory Compliance Standards

International regulations, such as the EU’s 852/2004 and the U.S. FSMA, require constant temperature monitoring at every stage—from raw material reception to final service.

-

- Non-compliance can lead to hefty fines, temporary closures, and irreparable reputational harm.

4/ The cost of mistakes

-

- The World Health Organization (WHO) reports that 1 in 10 people worldwide suffers from foodborne illnesses annually, resulting in roughly 420,000 deaths.

- A significant portion of these cases is linked to poor time and temperature management in processed or served food.

A robust and continuous monitoring system does more than protect consumers’ health—it builds trust in your business, enhances operational efficiency, and prevents substantial financial losses.

Common Failures in Time and Temperature Control

Failures in managing time and temperature within professional kitchens are more frequent than you might expect.

Below, we explore the most common errors, their consequences, and how to prevent them effectively.

1/ Improper Thawing

Many kitchens defrost food at room temperature or under warm water to speed up the process. However, this practice allows food to enter the “danger zone” (4°C to 60°C) where pathogens thrive.

Solution: Use safe methods, such as thawing in refrigerators with controlled temperatures or in defrost ovens set to specific programs.

2/ Insufficient Refrigeration

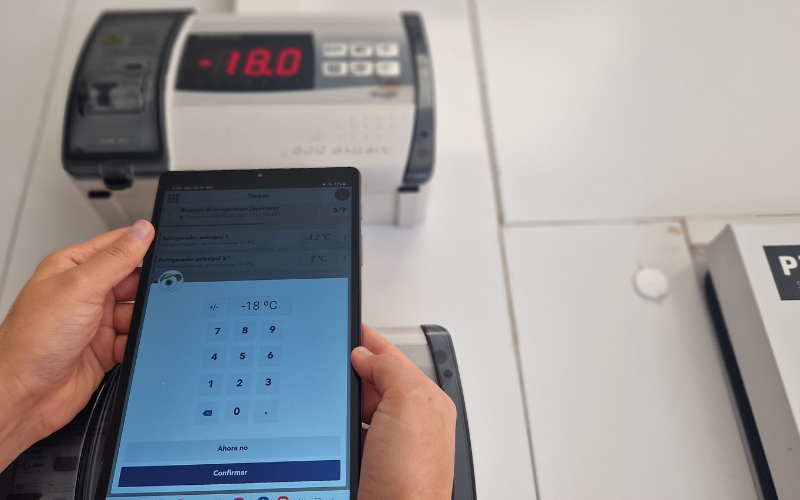

Refrigeration units that are poorly calibrated, overloaded, or experiencing technical issues often fail to maintain a constant temperature. These issues can go unnoticed until significant damage occurs.

Solution: Regular inspections, calibration adjustments, and real-time monitoring with temperature sensors.

3/ Improper Handling of Leftovers

Storing leftovers without rapid cooling or leaving them at room temperature fosters an environment ideal for bacteria like Clostridium perfringens.

Key Fact: Clostridium perfringens can reach dangerous levels in under two hours if leftovers aren’t cooled properly.

Solution: Divide leftovers into smaller portions and store them in shallow containers for faster cooling.

4/ Cooking at Inadequate Temperatures

Undercooking foods, especially meats, eggs, and dairy products, leaves harmful bacteria intact.

Regulations: Most standards require internal meat temperatures between 63°C and 75°C, depending on the type, to ensure safety.

Solution: Use digital food thermometers to verify internal temperatures.

5/ Cold Chain Breakdowns during Transportations

Transporting perishable goods at improper temperatures compromises food safety before products even reach the kitchen.

Key Fact: According to FAO, 20% of food losses in supply chains result from poor temperature management during transport.

Solution: Employ vehicles with continuous temperature monitoring and checkpoints along delivery routes.

6/ Prolonged Exposure During Service

Buffets or extended service hours can keep food in the danger zone for too long—a common issue in events or school and workplace cafeterias.

Consequences: Foods left at room temperature for over two hours are high-risk.

Solution: Rotate dishes frequently and utilise heating or cooling equipment to maintain safe temperatures.

7/ Lack of Controls for Incoming Goods

Suppliers may deliver products that have already been exposed to poor cold-chain practices. Without proper checks, these risks remain undetected.

Solution: Inspect and measure the temperature of goods upon delivery.

8/ Lack of Training and Real Time Monitoring

Human error remains a significant factor. Without proper training, employees may underestimate the importance of time and temperature controls.

Solution: Conduct periodic training sessions, reinforced with technology like digital assistants and automatic temperature sensors.

The Economic Impact of Poor Food Safety Management

Failing to manage time and temperature effectively endangers public health while also leading to significant economic repercussions for food service businesses.

1/ Direct Losses

- Food Waste: Faulty refrigeration, transport, or storage leads to significant waste.

Key Fact: FAO reports that 14% of global food loss occurs post-harvest and during storage due to cold-chain failures. - Additional Costs: Replacing spoiled inventory incurs transportation and storage expenses.

2/ Fines and Sanctions

- Regulatory Compliance: Laws like EU Regulation 852/2004 mandate stringent monitoring and clear temperature control records. Severe breaches can result in fines exceeding €10,000 per incident.

- Cumulative Effects: Temporary closures from non-compliance lead to substantial revenue losses.

3/ Reputational Damage

- Loss of Customers: Foodborne illness outbreaks severely erode consumer trust. Studies reveal that over 60% of customers avoid establishments involved in safety incidents, even after corrective measures.

- Public Relations Costs: Rebuilding a tarnished reputation through media campaigns and damage control drains valuable resources.

4/ Increased Insurance Premiums

- Repeated safety failures can lead to higher insurance premiums as providers adjust rates based on prior risks.

5/ Legal Expenses

- Foodborne illness outbreaks often result in lawsuits. According to the U.S. National Restaurant Association, food safety litigation costs average €75,000 per case.