Food safety in food service: improve it with Kaizen’s PDCA Cycle

Maintaining high food safety and quality standards in professional food service kitchens can be challenging, especially in fast-paced and complex operations.

The daily pressure to comply with regulations, prevent contamination, and meet customer expectations can overwhelm teams, making even well-designed processes prone to errors.

In this context, employing proven strategies for continuous improvement becomes essential to ensure food safety is not just a temporary goal but a sustained standard.

This is where the Kaizen philosophy, emphasising incremental, constant process optimisation, and the PDCA (Plan-Do-Check-Act) cycle, a structured tool for iterative improvements, come into play. Together, they offer a clear path to transforming food safety management in food service kitchens.

By proactively identifying and solving problems, these methods help build a culture of excellence, engaging the entire team to ensure safer and more efficient operations.

Let’s find out more.

What is Kaizen?

Kaizen is a Japanese management philosophy meaning “continuous improvement.” It revolves around the idea that even the smallest, most routine processes can be continuously improved. Rather than relying on sweeping, one-time changes, Kaizen focuses on gradual, consistent adjustments that lead to significant long-term results.

What makes Kaizen unique is its collaborative approach: everyone, regardless of their role, is encouraged and empowered to contribute to improvements

In the context of food safety, Kaizen fosters a culture where every team member—from chefs to cleaning staff—seeks to optimize both operational processes and safety standards. This could mean spotting inefficiencies, preventing contamination risks, and ensuring best practices evolve daily.

This collective effort enhances not only food safety but also team collaboration and morale, creating an environment where continuous improvement becomes second nature.

Why apply Kaizen to food safety?

n food service, food safety hinges on consistent, precise, and repeatable processes. Yet, these processes can deteriorate over time due to routine fatigue, staff burnout, or lack of proper oversight.

Kaizen serves as a vital tool in maintaining and improving these processes, yielding multiple benefits:

1/Proactive Risk and Inefficiency Identification: Continuous review of processes helps detect and address potential issues—like cross-contamination risks or inconsistent temperature controls—before they escalate into major incidents.

2/ Cultivation of a Collective Improvement Culture: Engaging the whole team in identifying and implementing solutions fosters shared responsibility and commitment to safe practices.

3/ Reduction of Critical Errors: Small, daily adjustments minimise the chance of mistakes in key areas such as food storage, labelling, and handling.

4/ Adaptability to Change: Kaizen equips teams to respond effectively to new regulations, technologies, or operational challenges, ensuring high food safety standards are maintained.

By embedding Kaizen into food safety practices, your food service kitchens will not only meet regulatory standards but will also establish stronger, more efficient, and sustainable processes.

The PDCA Cycle: Kaizen’s Operative Backbone

The PDCA Cycle (Plan-Do-Check-Act) is an essential tool within Kaizen, designed to ensure continuous improvement through structured, iterative steps.

It is particularly effective for upholding high food safety standards in food service because it provides a clear framework for identifying and resolving issues sustainably.

Each stage in the cycle plays a key role in the process of improvement:

1/ Planning: Identify specific areas requiring improvement – such as inconsistent temperature monitoring or poor cross-contamination prevention. Define clear objectives and strategies to tackle these issues.

2/ Doing: Implement solutions on a small, controlled scale. For instance, test a new method for temperature recording or enhanced cleaning protocols.

3/ Checking: Evaluate the outcomes of the initial implementation. Did the changes improve efficiency? Did they enhance food safety?

4. Acting: If successful, standardise the improvements across operations. If not, refine strategies and restart the cycle for further refinement.

The PDCA Cycle is particularly effective in food service because it tackles dynamic and complex issues with an iterative approach, continuously adapting to new regulations, technologies, and operational challenges.

By applying this cycle systematically, your kitchens ensure a safer, more efficient environment that aligns with food safety standards.

How does Andy help you manage the PDCA Cycle?

Andy is our digital assistant specialising in food safety and operations for food service used by leading food service brands worldwide.

It makes implementing the PDCA Cycle seamless by automating critical tasks, minimising human error, and freeing up time for teams to focus on strategic improvements.

Here’s how Andy contributes to each PDCA stage:

1/ Planning:

Andy streamlines the creation of Standard Operating Procedures (SOPs) and centralises them for easy team access, ensuring consistent adherence to food safety practices from the outset.

Additionally, Andy enables the prioritisation of actions based on historical data and identified risks.

2/ Doing:

With digital checklists and real-time reminders, Andy ensures critical tasks – such as HACCP monitoring, expiration labelling, and preventative maintenance – are executed on time, reducing non-compliance risks.

3/ Checking:

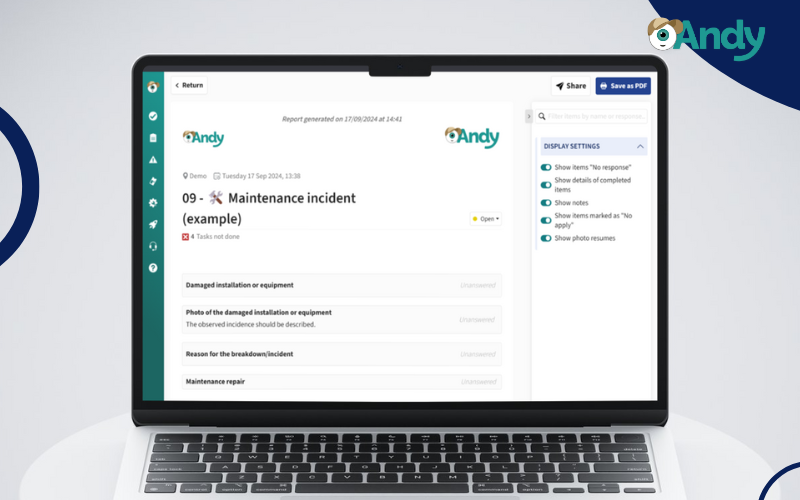

Andy automatically collects and organises essential data, like temperature logs and cleaning schedules, into visual reports.

Managers can quickly assess compliance and identify risks in real time.

4/ Acting:

Through detailed analytics and trend insights, Andy helps teams refine processes, resolve recurring issues, and scale successful practices across locations.

Andy also streamlines internal communication, ensuring that the entire team is aligned with newly implemented actions.

Andy’s additional feature to improve food safety management in food service kitchens

Además de gestionar el ciclo PDCA, Andy apoya a los equipos en tareas específicas como:

Beyond supporting the PDCA Cycle, Andy enhances food safety management with tools like:

-

- HACCP Monitoring: Automated alerts and incident notifications.

- Expiration Labelling: Clear, accurate labeling to prevent confusion.

- Audits and Corrective Actions: Simplified oversight and resolution tracking.

- Digital Library: A centralised hub for up-to-date regulatory documents and guidelines.

Build a culture of continuous improvement with Kaizen’s PDCA Cycle and Andy

Adopting the Kaizen approach and PDCA Cycle fosters a culture of continuous improvement that benefits both your team and your customers.

This method not only ensures compliance but also promotes safer, more efficient, and more resilient kitchen operations.

With Andy, implementing PDCA is easier than ever. From automating tasks to providing actionable insights, Andy empowers your team to not just meet food safety standards but exceed them consistently.