13 Key performance indicators for kitchen operations

Understanding and tracking the right KPIs is crucial for optimising kitchen performance, reducing costs, and delivering exceptional customer experiences.

By carefully monitoring these metrics, you can identify areas for improvement, make data-driven decisions, and achieve operational excellence.

But what are the key performance indicators for kitchen operations?

What do you measure and how do you measure it?

Find out more in this post!

Core key performance indicators for kitchen operations

By meticulously tracking and analysing the following metrics, you can gain valuable insights into your kitchen’s performance, identify areas for improvement, and make data-driven decisions to optimise efficiency and profitability.

1 Food Cost Percentage

The food cost percentage measures the ratio of food expenses to food sales. By closely monitoring this metric, you can identify areas of potential cost savings, such as reducing waste, negotiating better prices with suppliers, or optimising menu pricing.

2 Labor Cost Percentage

This KPI evaluates the efficiency of your staffing levels. By tracking labour costs against sales, you can identify opportunities to optimize schedules, increase productivity, or reduce overtime.

3 Prime Cost Percentage

Combining food and labour costs, the prime cost percentage offers a comprehensive view of your overall operational expenses. This metric helps you assess the efficiency of your kitchen operations and identify areas where cost reductions can be implemented.

4 Inventory Turnover

Inventory turnover measures how efficiently you manage your stock. A high turnover rate indicates effective inventory management, while a low turnover rate may signal issues such as overstocking or slow-moving items.

5 Menu Item Profitability

Analysing the profitability of individual menu items helps identify your most profitable offerings and pinpoint areas where prices may need adjustment or where cost reductions can be implemented.

6 Order Accuracy

This KPI measures the percentage of orders prepared and served correctly. High order accuracy is essential for customer satisfaction and repeat business.

7 Order Turnaround Time

Tracking the time it takes to prepare and serve orders provides valuable insights into kitchen efficiency and customer satisfaction. Reducing order turnaround time can lead to increased customer satisfaction and higher table turnover.

8 Food Waste

Quantifying food waste helps identify areas of inefficiency and loss. By reducing food waste, you can improve profitability and demonstrate a commitment to sustainability.

Additional Key Performance Indicators for Food Service Kitchens

While the core KPIs provide a foundational understanding of kitchen performance, a deeper dive into specific metrics can offer invaluable insights into areas often overlooked.

These additional KPIs can help you identify opportunities for improvement in areas such as human capital, equipment management, and customer experience.

9 Employee Turnover Rate

High employee turnover can be costly and disruptive to kitchen operations. Tracking this KPI helps identify issues with workplace culture, compensation, or working conditions. By addressing the root causes of turnover, you can improve staff retention and create a more stable work environment.

10 Employee Satisfaction

Engaged employees are more productive and provide better customer service. Measuring employee satisfaction through surveys, feedback sessions, or other methods can help identify areas for improvement in workplace culture, working conditions, and employee recognition.

11 Equipment Uptime

Reliable kitchen equipment is essential for efficient operations. Tracking equipment uptime helps identify equipment that is prone to breakdowns, allowing for proactive maintenance and reducing downtime.

12 Energy Consumption

Monitoring energy consumption can help identify opportunities for cost savings and reduce your environmental impact. By tracking energy usage in different areas of the kitchen, you can identify equipment or processes that are particularly energy-intensive and implement energy-saving measures.

13 Customer Satisfaction

Ultimately, the success of your kitchen depends on customer satisfaction. By measuring customer feedback on food quality, service, and overall dining experience, you can identify areas for improvement and implement changes to enhance customer loyalty.

By incorporating these additional KPIs into your performance measurement strategy, you can gain a more comprehensive understanding of your kitchen’s operations and make data-driven decisions to drive continuous improvement.

Turning Kitchen KPIs into Action with Andy

Identifying the right KPIs is only the first step.

The real challenge is transforming numbers on a spreadsheet into day-to-day improvements that boost efficiency, reduce waste, and guarantee compliance.

This is where Andy, the leading digital assistant for food service, food retail, institutional catering and hotels, marks the difference.

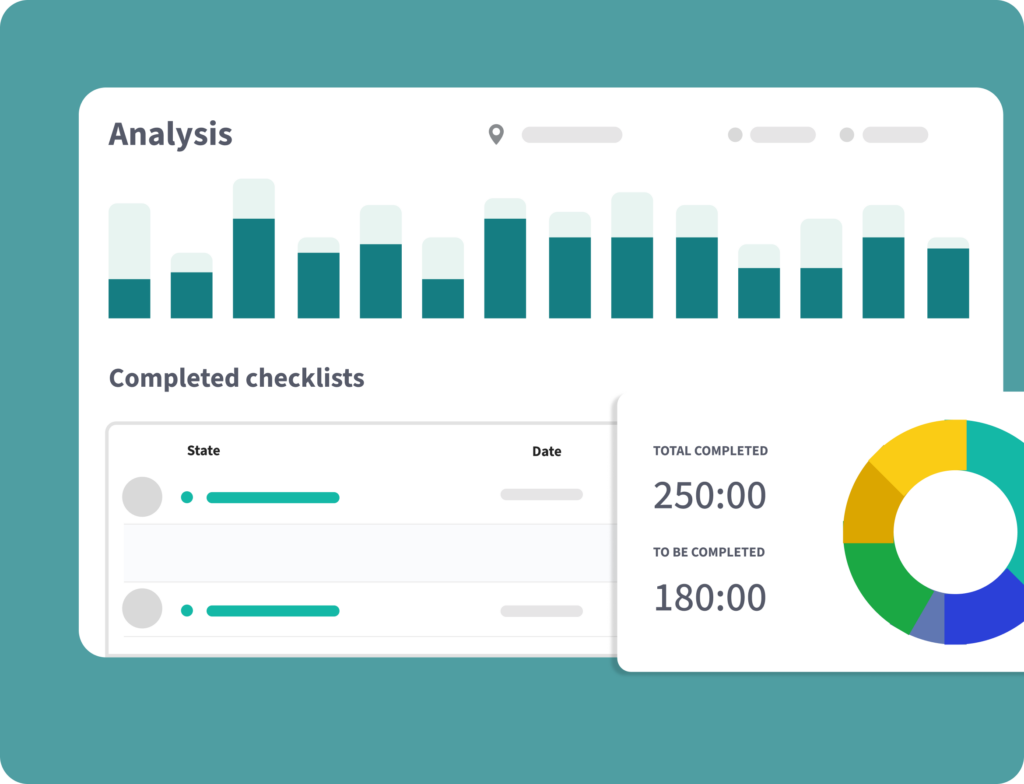

From Data to Insights

Many kitchens measure KPIs such as food waste, audit scores, or staff productivity, but struggle to interpret what the data actually means.

Andy centralises every metric into a clear, real-time dashboard. Instead of scattered notes, Excel files, or manual logs, managers get one single source of truth. This makes it easier to spot trends – for example, a sudden spike in expiry-related waste – and act before it becomes a costly issue.

Automation and Real-Time Alerts

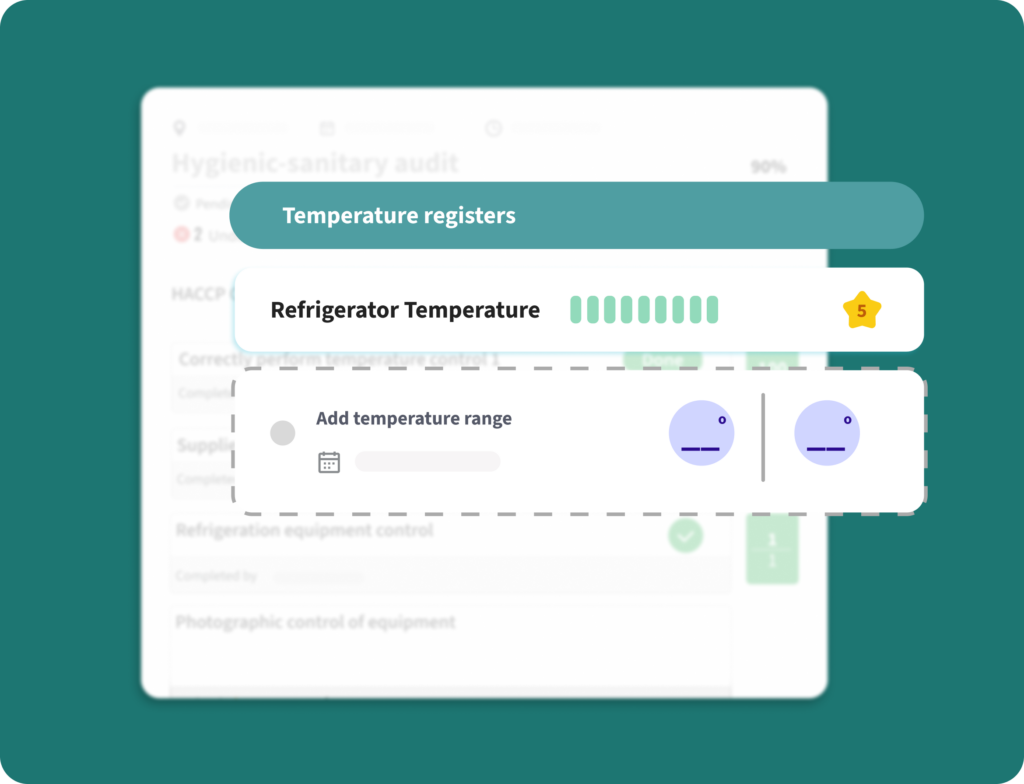

KPIs are most valuable when they drive immediate action. Andy automates the process by:

-

Sending real-time alerts when critical limits are exceeded (e.g. fridge temperatures).

-

Flagging non-compliance before it turns into an audit failure.

-

Streamlining labelling, HACCP records, and incident reports -reducing paperwork by up to 40%.

This automation ensures that kitchen teams don’t just track performance, they actively improve it in the moment.

Engaging and Empowering the Team

KPIs are not only about numbers; they are also about people.

Andy functions as an extra team member – guiding chefs, servers, and managers with digital checklists, reminders, and friendly prompts. This creates a culture of accountability and continuous learning, where everyone understands how their role contributes to wider performance targets.

Closing the Loop: Continuous Improvement

KPIs should never be static.

With Andy, the measurement cycle becomes a continuous improvement loop:

-

KPIs are tracked automatically.

-

Insights are displayed on Andy’s dashboards.

-

Managers identify patterns and make quick adjustments.

-

Improvements are monitored and celebrated in real time.

This loop guarantees that performance is not only measured but also sustained and optimised over the long term.

Andy: Your Partner in KPI Management

Understanding and tracking KPIs is essential, but manually collecting and analysing data can be time-consuming and error-prone.

This is where Andy, your digital food safety and operational excellence assistant, comes in.

Andy’s Auditing tool simplifies KPI management by:

- Automating data collection: Andy’s intelligent system can collect data on various aspects of your kitchen operations, such as food safety, operational and efficiency saving you valuable time and effort.

- Providing real-time insights: With Andy, you can access up-to-date performance metrics, allowing you to make informed decisions quickly.

- Identifying trends and patterns: Andy’s advanced analytics capabilities help you uncover hidden trends and patterns in your data, enabling you to address issues proactively.

- Generating actionable reports: Andy provides clear and concise reports that highlight key performance indicators, making it easy to communicate findings to your team.

By leveraging Andy’s capabilities, you can streamline your KPI management process, gain deeper insights into your kitchen operations, and ultimately drive improved performance.

Ready to transform your KPIs into real operational improvements?

Start with Andy today and discover how the leading digital assistant for food service, hospitality, and retail can help your kitchen thrive.