¿Food Safety Fatigue? The hidden risk in professional kitchens

Is the Pressure to Maintain Food Safety Standards Draining Your Team?

In professional kitchens, food safety should be a sturdy pillar of operations. Yet, in many cases, it’s becoming an increasingly heavy burden.

The growing complexity of regulations, coupled with rising compliance demands, has given rise to a concerning phenomenon: food safety fatigue.

This term captures the physical and mental strain experienced by teams grappling with an endless stream of audits, checklists, and repetitive manual tasks. Inevitably, this fatigue heightens the risk of human error, regulatory violations, and consumer health hazards – along with jeopardising the reputation of businesses.

But how does this fatigue arise, and what can you do to protect your team while maintaining the highest standards?

This article breaks down the causes and solutions to ensure food safety remains a manageable and sustainable priority.

The hidden cost of compliance overload

Professional kitchens today face monumental challenges, from adhering to detailed allergen labelling to precise temperature controls and rigorous cross-contamination prevention.

While these measures are essential for consumer protection, implementing them manually without proper support can overwhelm teams.

- A Deloitte study found that 58% of food service employees feel burdened by the volume of food safety tasks, creating a stress-prone and error-laden environment.

- Food Safety Magazine reports that repetitive manual tasks, such as compliance logs, increase the likelihood of errors by 40%, directly affecting operational efficiency.

The issue isn’t just the workload but how it’s perceived.

A Cornell University survey revealed that 72% of workers admitted to cutting corners under pressure, reflecting inadequately designed systems that lack flexibility.

The financial repercussions are staggering.

Major incidents, such as cross-contamination, can lead to foodborne illness outbreaks, irreparably damaging a brand’s reputation and incurring significant losses.

According to the Food Marketing Institute, a serious contamination incident can cost a business up to $10 million in litigation, compensation, and lost consumer trust.

Additionally, constant audits and scrutiny take a psychological toll, leading to emotional exhaustion, demotivation, and high staff turnover, which further disrupts business performance.

Combating Food Safety Fatigue While Upholding Standards

The key to mitigating food safety fatigue lies in sustainable strategies that not only uphold standards but also make them easier to achieve.

Here’s a comprehensive approach based on three key pillars:

1/ Streamline processes to lighten the load

Complex and redundant workflows are a recipe for frustration.

Simplify tasks, consolidate efforts, and design efficient systems to save time and improve accuracy.

- Integrated platforms that combine audits, inventory, and monitoring can reduce administrative workload by up to 40%, as seen in businesses adopting Andy.

- Streamlined protocols are easier for staff to follow, increasing compliance rates and reducing resistance.

2/ Emphasise meaningful continuous education

Training must go beyond rote instructions. Help staff understand the “why” behind each protocol to foster emotional buy-in and responsibility.

- Harvard Business Review found that combining interactive training with practical scenarios boosts compliance by 40%.

- Engaging approaches like gamified workshops or real-world simulations keep teams motivated and invested.

3/ Leverage Smart Technology as a strategic ally

Technology isn’t about replacing people—it’s about empowering them by automating repetitive tasks and reducing errors.

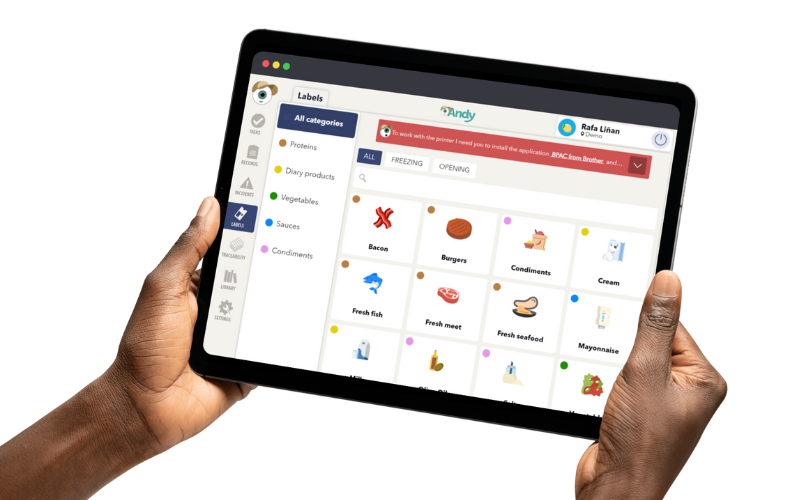

Tools such as real-time temperature sensors, dynamic checklists, and digital labelling systems transform food safety management.

A Deloitte report showed a 22% reduction in incidents and a 30% decrease in compliance issues in businesses using digital solutions.

These technologies also offer instant alerts and predictive insights, enabling swift responses to emerging risks while protecting both consumers and brand reputation.

Building a sustainable Food Safety Culture

These strategies don’t work in isolation.

Their real impact lies in combining them to create a comprehensive, integrated system.

Simplifying workflows, educating staff, and using advanced tools together helps businesses combat fatigue while embedding food safety into their DNA.

How Andy supports continuous improvement

Andy is more than a digital tool—it’s a true partner in transforming food safety management for the food service industry.

Andy’s capabilities include:

- Digital HACCP Management:Automates task tracking and ensures compliance without adding extra workload.

- Smart Expiration Labels: Manages secondary expiration dates automatically, reducing errors and waste.

- Dynamic, simplified Audits: Centralised real-time reporting saves hours of manual work.

- Proactive Alerts and Incident Management: Detects issues instantly and prompts immediate action.

- Preventive Maintenace: Keeps equipment in optimal condition with automated schedules.

Businesses using Andy report up to a 40% reduction in manual workload and a 90% decrease in compliance errors. .

Centralised data access and trend analysis further optimise processes and enable informed decision-making.

Towards a Smarter, more Suistainable Model

Food safety fatigue is a growing challenge—but it’s not insurmountable. By streamlining processes, prioritizing team training, and embracing advanced tools like Andy, kitchens can balance rigorous standards with a healthy work environment.

In today’s competitive food service industry, the real question is:

Can your business afford not to adopt smarter, more sustainable strategies?