Leveraging Data in Food Service Kitchens to Drive Efficiency and Profitability

Imagine navigating a complex maze without a map or compass.

Nearly impossible, right?

That’s not at all unlike running a food service business without data analytics. Or similar to making decisions based on intuition rather than evidence.

Without data in food service businesses, it’s like trying to hit a moving target in the dark.

By harnessing the power of data, food service businesses can not only gain invaluable insights into operations, customer preferences, and market trends, but also make informed choices based on data-driven insights, increase revenue and reduce costs through targeted strategies.

In this article, we explore how data in food service business can be used to drive efficiency, profitability, and customer satisfaction.

The Power of Data in Food Service Kitchens

Data analytics provides a wealth of information that can be used to improve various aspects of a food service business.

Without the right insights, even the most talented teams can find themselves navigating a maze of inefficiencies and missed opportunities.

Kitchen automation systems generate a wealth of data that can be harnessed to revolutionise operations. By analysing this data, food service businesses can:

- Optimise Equipment Utilisation: Identify underutilized or overworked equipment, enabling more efficient resource allocation and maintenance scheduling.

- Prevent Food Waste: Monitor food temperatures, track inventory levels, and predict demand to minimise waste and reduce costs.

- Enhance Food Safety: Ensure compliance with food safety regulations and prevent foodborne illnesses by tracking critical control points and monitoring equipment performance.

- Improve Efficiency: Streamline workflows, reduce preparation times, and enhance overall productivity.

- Personalise Menus: Analyse customer preferences to tailor menu offerings and increase satisfaction.

Key Performance Indicators (KPIs) to Track:

- Equipment Utilisation: Monitor the percentage of time equipment is in use and identify idle periods.

- Food Waste: Track the amount of food wasted and identify the root causes.

- Preparation Time: Measure the time it takes to prepare dishes and identify areas for improvement.

- Energy Consumption: Monitor energy usage to identify opportunities for conservation.

- Employee Productivity: Track employee performance and identify training needs.

Harnessing the Power of Predictive Data Analytics in Food Service Kitchens

Predictive analytics – a subset of data science -, can revolutionise the way food service kitchens operate.

By analysing historical data and identifying patterns, businesses can gain valuable insights into future trends and make informed decisions.

Key Applications of Predictive Data Analytics in Food service

- Demand Forecasting:

- Predicting peak times: Anticipate busy periods to optimise staffing levels and avoid bottlenecks.

- Forecasting ingredient demand: Accurately predict the demand for ingredients, reducing the risk of stockouts or overstocking.

- Equipment Maintenance:

- Predictive maintenance: Use data to predict equipment failures and schedule maintenance proactively, preventing downtime and reducing costs.

- Food Safety:

- Identifying risk factors: Analyse data to identify potential food safety hazards and implement preventive measures.

- Predicting outbreaks: Use historical data to predict the likelihood of foodborne illness outbreaks and take proactive steps to prevent them.

Benefits of Predictive Analytics

- Improved Efficiency: By anticipating future trends, businesses can optimise resource allocation and reduce waste.

- Enhanced Decision Making: Predictive analytics provides data-driven insights to support informed decision-making.

- Cost Savings: By preventing equipment failures, reducing waste, and optimising operations, businesses can achieve significant cost savings.

- Enhanced Customer Experience: By accurately predicting demand, businesses can ensure that customers are served efficiently and avoid long wait times.

Implementing Predictive Analytics in Food Service Kitchens

To effectively leverage predictive analytics, foodservice businesses should:

- Collect and Store Data: Gather relevant data from various sources, including digital assistants, inventory management software, and equipment sensors.

- Choose the Right Tools: Select appropriate analytics software that can handle large datasets and perform complex calculations.

- Continuously Monitor and Refine: Regularly review and update predictive models to ensure their accuracy and relevance.

By implementing predictive analytics, food service kitchens can gain a competitive edge, improve efficiency, and enhance the overall customer experience.

Leveraging 🧢Andy for Data-Driven Insights in Food Service Kitchens

Andy is a cutting-edge digital assistant designed for foodservice businesses.

It offers a comprehensive suite of tools designed to help you manage operations and food safety protocols, providing valuable insights that can drive operational efficiency and improve food safety.

Temperature Monitoring

- Real-time data: Andy’s temperature monitoring capabilities provide real-time data on equipment temperatures, ensuring compliance with food safety regulations and preventing foodborne illnesses.

- Alerts and notifications: The platform can send alerts and notifications when temperatures deviate from predefined parameters, allowing for immediate corrective action.

- Data analysis: Andy can analyse historical temperature data to identify trends and patterns, helping businesses optimise storage conditions and reduce food waste.

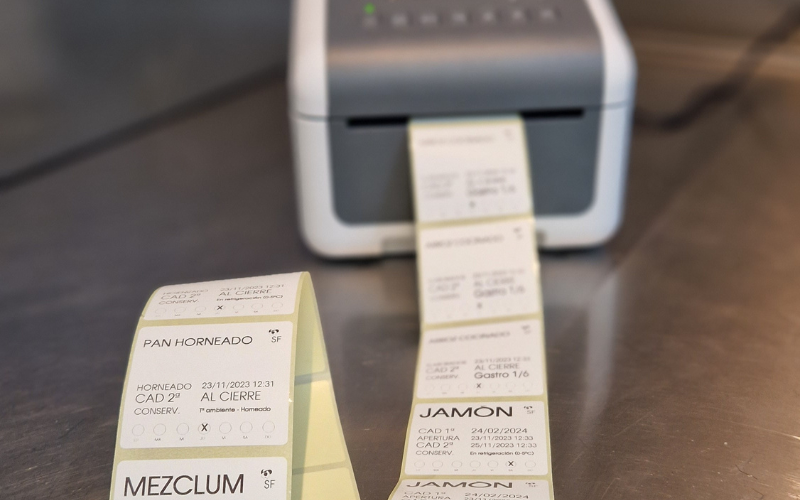

Automated Food Labelling

- Accuracy and consistency: Automated food labelling ensures accurate and consistent labelling, reducing the risk of errors and improving customer satisfaction.

- Data collection: Andy can collect data on food labels, such as ingredients, allergens, and nutritional information, for analysis and reporting.

- Compliance: Automated labelling can help businesses comply with food lableling regulations and avoid costly penalties.

Traceability

- Ingredient tracking: Andy can track ingredients from source to finished product, enabling businesses to identify the root cause of any food safety issues.

- Allergen management: The platform can help manage allergens and prevent cross-contamination, ensuring the safety of customers with dietary restrictions.

- Supply chain visibility: Andy provides visibility into the entire supply chain, allowing businesses to identify potential risks and disruptions.

Internal Auditing

- Automated checklists: Andy can automate internal audit checklists, ensuring consistency and compliance with food safety standards.

- Data analysis: The platform can analyse audit data to identify trends, areas for improvement, and potential risks.

- Compliance reporting: Andy can generate comprehensive compliance reports for regulatory purposes.

Communication

- Real-time communication: Andy enables real-time communication between kitchen staff, management, and other stakeholders, improving collaboration and efficiency.

- Task management: The platform can be used to assign tasks, track progress, and ensure accountability.

- Document management: Andy can store and manage important documents, such as training records, SOPs, and audit reports.

Preventive Maintenance

- Equipment tracking: Andy can track equipment usage, maintenance history, and performance data to predict failures and schedule preventive maintenance.

- Cost savings: By preventing equipment breakdowns, businesses can reduce downtime, maintenance costs, and food waste.

- Improved efficiency: Well-maintained equipment operates more efficiently, leading to improved productivity and reduced energy consumption.

Incident Management

- Incident reporting: Andy can be used to report and track incidents, such as foodborne illnesses or equipment failures.

- Root cause analysis: The platform can help identify the root causes of incidents and implement corrective actions to prevent recurrence.

- Compliance reporting: Andy can generate reports on incident management activities for regulatory purposes.

By leveraging Andy’s capabilities, food service businesses can gain valuable insights into their operations, improve efficiency, enhance food safety, and ensure compliance with regulations.

From temperature monitoring and automated food labelling to traceability, internal auditing, and communication, Andy provides the insights needed to make data-driven decisions and optimise kitchen operations to their maximum potential!

Don’t operate blindfolded!

👉🏽START WITH ANDY TODAY!👈🏽