Food Service Operations 2026: 10 Practices You Must Leave Behind to Scale Successfully

2026 isn’t arriving gently — it’s arriving with pressure. New regulations, more informed consumers, stricter audits, smaller margins for error, and higher staff turnover.

In this context, food service operations in 2026 need a deep clean.

If you want to scale without losing consistency, it’s time to let go of what no longer works. Here are the 10 practices the industry must leave behind—and the alternatives that will prepare you for a more agile, secure, and efficient 2026.

Food Service Operations 2026: 10 Practices You Must Leave Behind to Scale Successfully

1. Leaving paper behind

Paper records aren’t just outdated… they’re an operational risk.

They get lost, mixed up, offer no real traceability, and slow down audits.

What to do in 2026:

Digitise tasks, checklists, HACCP, and traceability.

Less chaos, more control, more evidence.

2. Calculating expiry dates manually (the source of thousands of errors)

Calculate days → Subtract → Label → Recalculate if something is opened…

It’s the perfect recipe for mistakes.

2026 solution:

Automate expiry dates with smart logic.

Avoid human error and protect product integrity.

3. Operating without 24/7 temperature sensors

In 2026, temperature = a critical KPI.

Continuing to rely on manual measurements is like driving without a seatbelt.

What 2026 requires:

Connected sensors + alerts + dashboards.

Real reduction of risks and incidents.

4. Depending on “the most experienced staff member”

Your best employee cannot be your operating system.

In 2026, systems- not people – run operations.

Clear flows, structured tasks, fast onboarding.

5. Training without structure and verification

You explain. The team listens. And then… everyone does it their own way.

In 2026:

Digital checklists with evidence, roles, and micro-tasks.

Continuous training → real consistency.

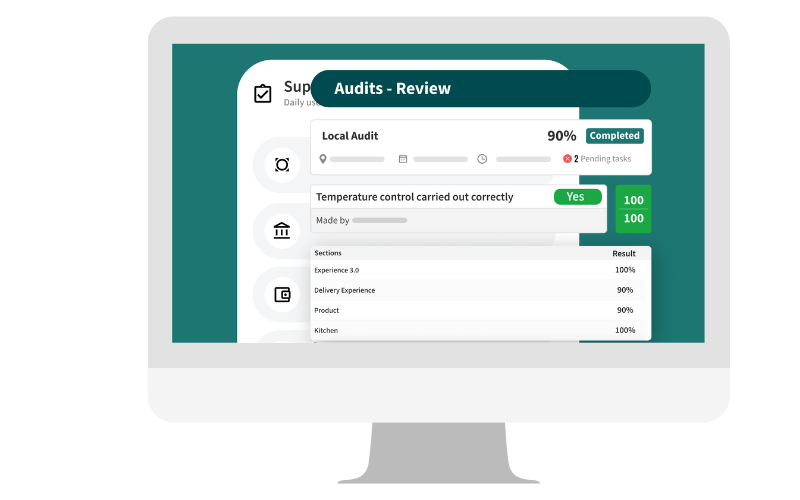

6. Improvised audits (or setting up operations only for the external auditor)

A far too common practice.

But it no longer works.

2026 solution:

Continuous evidence, automated traceability, one-click data access.

7. Daily records with no alerts or follow-ups

Static logs tell you nothing.

What you need is information that acts.

2026:

Systems with smart alerts + real-time data.

8. Running without preventive maintenance

Waiting for a machine to fail in 2026 means:

higher costs + product loss + stress + service interruption.

2026:

Automatic schedules + QR codes + maintenance traceability.

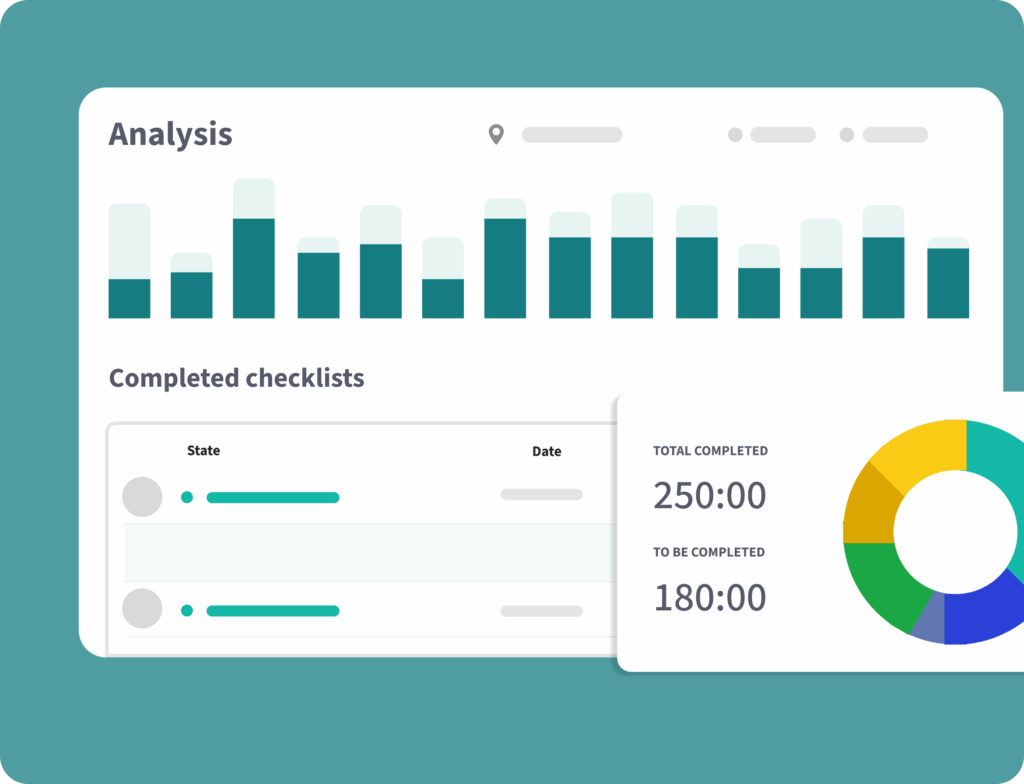

9. Lack of visibility across multiple locations

Distance is no longer an excuse.

If you operate multiple sites, you need global visibility.

2026:

Centralised dashboards, unified alerts, shared standards.

10. Confusing “being busy” with “being efficient”

2026 rewards efficiency, not frantic activity.

The key: fewer tasks, more impact.

Solution:

Automation → simplification → data-driven decisions.

2026 will be the year when brands that follow these principles take off… and those that don’t will keep fighting daily operational chaos.

If you want consistency, scalability, and real control, now is the time to redesign your operations for what’s coming.

Want to start 2026 with a simpler, safer, and more scalable operation?

👉 Discover Andy and digitise your food service operations 2026 with a system that actually works in real life.