Internal Food Temperature: everything you need to know

The internal temperature of the food you prepare in your kitchens is one of the most important cooking parameters for your teams.

The internal food temperature of your product dictates not only the quality of the final product, but it also guarantees the safety of your customers, and consequently, the health and reputation of your brand.

What happens then, if we take a key metric like internal temperature lightly, and don’t establish the correct protocols for measuring and taking action in the event of possible incidents?

As you can imagine, the consequences can be catastrophic.

Consequences which can be prevented by following the steps outlined below, and by properly training our foodservice teams.

Let’s go!

What is the internal food temperature?

The internal food temperature is considered to be the temperature that is recorded in the centre of the thickest part of the food we are preparing.

That thickest part of the food is the hardest to cook, because it is furthest from the outside and the heat source. And that is the part that tells us if we have reached the optimal cooking point from the point of view of quality and food safety.

What factors affect the internal food temperature?

Safe cooking temperatures vary depending on several different factors. These factors can include:

- The type of foodborne pathogen

- The composition of the food

- The cooking method

- The cooking time

- The desired level of cooking

Why is it so important to reach the minimum internal food temperature?

Achieving the minimum internal food temperature means effectively eliminating potentially harmful bacteria present in the raw material, which can be pathogens as harmful and dangerous to public health as Salmonella, Escherichia coli, and Norovirus.

Without proper food safety practices, pathogens can be contaminated through cross-contamination.

Complete cooking by applying heat is essential to inactivate different types of pathogens, and to keep our customers safe. Cooking and reaching the target internal temperature is often considered the last step in controlling foodborne pathogens and preventing food poisoning.

Cooking food to the correct internal temperature also makes it stable at room temperature. However, being able to withstand the temperature danger zone with less risk does not mean that adequate raw material reception controls and storage conditions are still not required.

How to measure the internal food temperature

Can we correctly measure the internal food temperature by looking at its colour and texture?

No.

Food thermometers are the only reliable way to measure the internal food temperature.

Many chefs believe that they can tell if food has reached the desired temperature by looking at its colour. However, colour is not a reliable indicator of doneness.

For example, ground beef may look cooked on the outside, but still be raw on the inside. Until ground beef reaches 68°F (20°C) in the center, it may still contain harmful bacteria and make customers sick.

Internal food temperature is not a matter of guesswork.

It is important to take the time to measure it with a clean thermometer designed for this purpose.

The most common type of food thermometer is the instant-read bimetallic thermometer (or pocket thermometer). These thermometers are affordable, easy to use, and very accurate if they are calibrated regularly.

To measure the internal temperature, insert the thermometer into the thickest part of the food, avoiding any bones or fat.

Leave the thermometer in place for 15-20 seconds (depending on the type of food you are cooking) to get an accurate reading.

As a practical guide, it is important to always follow the following steps to measure the internal food temperature correctly:

- Clean and disinfect the food thermometer probe.

- For solid foods: Insert the thermometer probe into the thickest part of the food, at least 1.3 centimeters (0.5 inches) deep.

- For liquid foods: Immerse the thermometer probe at least 1/4 of the way up from the bottom of the container.

- Allow the temperature reading to stabilize.

- Record the temperature reading and remove the thermometer.

- If you do not remember the correct temperature for each food, consult a cooking temperature chart.

- Clean and disinfect the food thermometer probe.

Do we follow the same process to measure the internal temperature of all foods?

While the process is the same, the measurement times will vary depending on the product.

Let’s have a look at the differences!

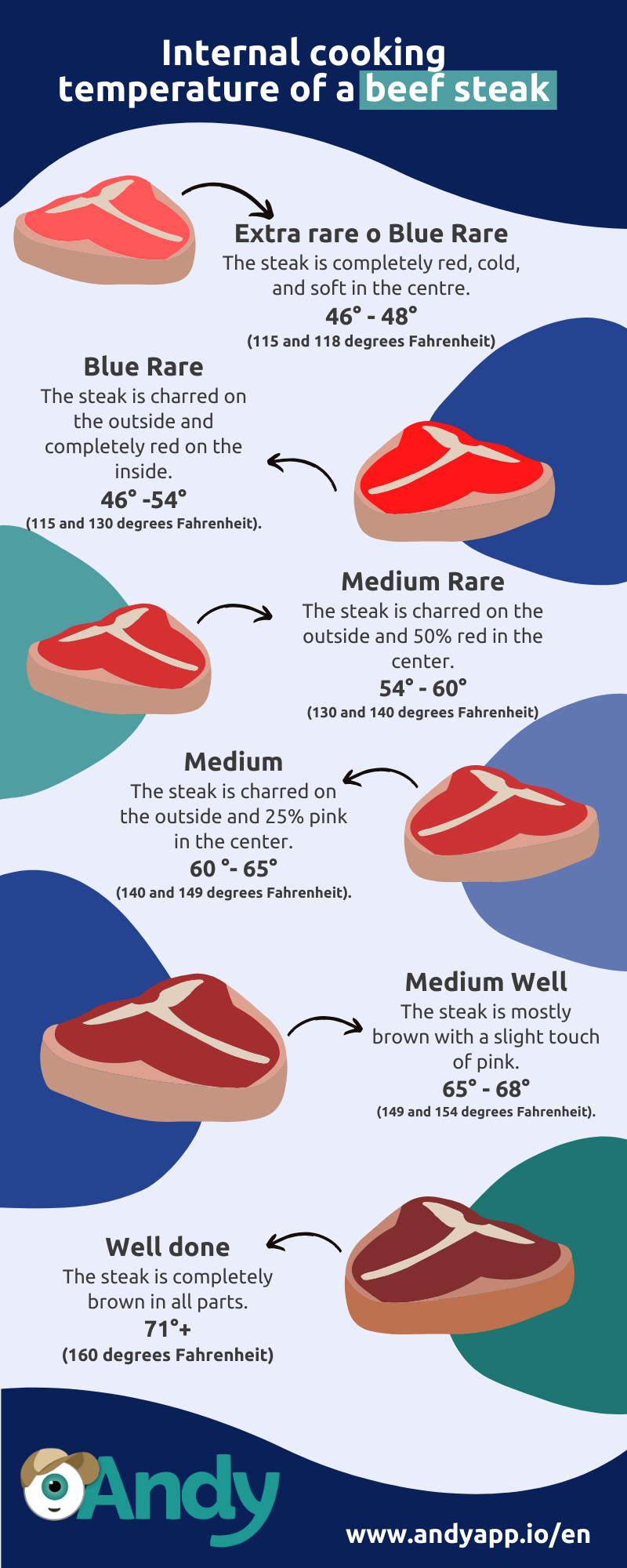

Internal temperatures of beef and lamb

The safest minimum internal cooking temperature for beef and lamb is 71°C (160°F). This level of cooking gives the meat a medium to medium-well done point of cooking, with a slightly pink centre, and a very appealing juiciness and texture.

Yes, many people have a personal preference for eating beef and other similar meats at a medium to medium-rare point of cooking.

In that case, the safe internal temperature to achieve those conditions must be 60°C (140°F).

What happens if these guidelines are not followed?

There is a risk of suffering an outbreak of some type of dangerous pathogen, such as E. coli, which is very common in beef and lamb.

We recommend that you have the following internal temperature charts displayed in a place easily accessible to all your staff:

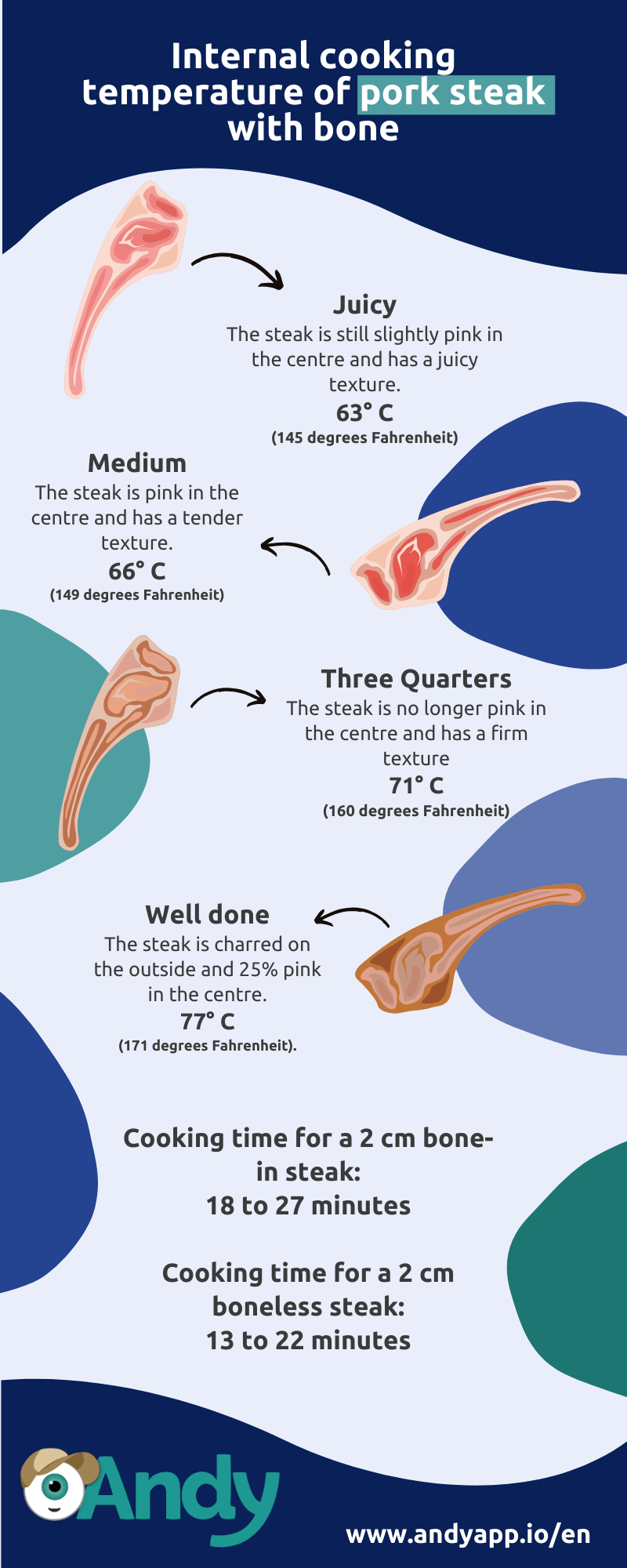

Internal temperature of pork

Pork is often involved in outbreaks of various pathogens, including Staphylococcus aureus, Clostridium perfringens, Salmonella, Listeria, and the parasite Trichinella spiralis.

Unlike beef, pork has less myoglobin, which is the pigment in blood that gives meat its red color.

The safe cooking temperature for pork is 63°C (145°F), as long as it has a three-minute resting time before being cut.

The following guide will help you remember the safe temperatures for each cut of pork:

Internal temperatures of poultry

Poultry meat includes chicken, turkey, goose, and game birds. To ensure food safety, raw poultry and poultry products must be cooked to an internal temperature of 74°C (165°F).

Any temperature lower increases the risk of foodborne illness, as has been the case with so many outbreaks caused by pathogens such as Salmonella and Campylobacter in this type of meat.

And yes, unlike pork and beef, the safe internal temperature of poultry has less margin of error.

To measure the internal temperature of a whole bird, such as a chicken, for example, we will insert the thermometer correctly into the thickest part of the chicken, which is the breast.

Internal temperature of ground meat

The problem with ground or minced meat is the grinding process.

It is very likely that during this process, pathogens already present in the machinery have passed into the meat. That is why, because more of the product’s surface has been exposed to various microorganisms, ground meat requires thorough cooking.

So, take note: the minimum cooking temperature for ground beef, pork, and veal is 71°C (160°F), while ground poultry must be cooked to an internal temperature of 74°C (165°F).

Internal temperature of eggs

Eggs and related products must be cooked to a minimum temperature of 71°C (160°F).

Like poultry, eggs pose a high risk of illness if not prepared properly.

Temperatura interna del pescado

Fish and seafood reach their ideal cooking point much sooner than other meats.

However, it is important to keep in mind that these products are carriers of pathogens such as Norovirus, Vibrio, and Salmonella, which can be transmitted through water.

To achieve the optimal balance between quality, texture, and flavor, on the one hand, and the optimal food safety point, on the other, fish and seafood must be cooked to an internal temperature of 63°C (145°F) for a few minutes.

Here is a general table of internal cooking temperatures for foods in your kitchens:

How do you reach the target internal temperature of each type of food?

You reach the ideal food temperature by combining a regulated application of heat, time, and constant monitoring.

In other words, by cooking it!

When we cook our food using different cooking methods, we apply heat and distribute it evenly until we reach the desired internal temperature in the centre of the food.

Of course, it is important to know what that desired internal temperature is, and to measure the food properly to know if we have reached the optimal degree or not.

It is important to keep in mind that the state of the food before it is cooked will significantly affect the distribution of heat.

Ideally, you need to cook the raw material at room temperature.

Frozen and refrigerated foods must be thawed before cooking.

Other foods will require a resting time to allow for uniform heat distribution across all surfaces of the food.

That’s it for now, but remember that this is just a tiny part of your food safety basics!

In addition to cooking food properly to the correct internal temperature, your food handlers must be constantly aware of general and specific food safety practices to keep the presence of pathogenic microorganisms to a minimum.

Because, while achieving adequate internal temperatures in meat is key, this operation can only be effective if the microbial load is not too high. With extremely high microbial loads, pathogens can spoil food very quickly or make the recommended cooking parameters insufficient.

Can technology help you ensure the internal food temperature in your kitchens?

Of course!

We invite you to read “How quickly does bacterial contamination in food spread and how to prevent it ”, as a complement to this article, and to get an idea of how a digital assistant like Andy can guide and systematise the essential tasks in the day-to-day operations of your establishments, including that tedious temperature recording!

With Andy, you can carry out all HACCP, temperature, hygiene, raw material reception, etc. records, in a fully automated and personalised way.

In addition, Andy identifies alerts and proposes action plans in case of incidents.

With Andy you can rest assured that your employees will never miss a control point to check your food’s temperature danger zone!

Currently, restaurants that already work with Andy, measure another very important metric: the internal temperature of cooked and reheated food.

Our “partners” use Andy to monitor the first foods that are prepared in the morning shift and the first ones in the evening shift.

They measure the temperature of one product from each equipment (fryer, oven, bain-marie, etc.), without forgetting the microwave (reheating), unifying the temperature of Critical Control Point as >=65ºC.

In this way, they ensure that the food never exceeds the critical limit while verifying the correct functioning of the machinery.

This is very important for the correct configuration of action plans, where Andy guides them at all times.

Why don’t you try for yourself the many advantages that Andy App can bring to your business?