Food Safety in Burger Restaurants: Risks, HACCP and Quality Control

Food Safety in Burger Restaurants: Risks, HACCP and Quality Control.

How do I know if the burger ingredients are safe to eat?

How does the burger joint ensure the quality of the meat they use?

Do they handle the meat correctly to prevent food safety incidents?

Will they know how to cook my burger properly?

Will it get spoiled in delivery?

These are just some of the questions we, as consumers, ask ourselves every day before eating a professionally prepared burger.

Because that’s exactly how consumers are today! Savvy, demanding, and interested in food safety processes!

The team at Andy works with numerous burger restaurants daily, and we know how important food safety is for your customers, your teams, and of course, for you, the owner and/or quality manager.

That’s why we’ve prepared this extensive guide to food safety in burger restaurants.

We want to leave no doubt about the processes to follow to guarantee the health of customers who trust your brand.

So, let’s go!

First step: Your suppliers.

Controlling the Quality of Raw Materials from Suppliers in a Burger Restaurant

To control the quality of raw materials from suppliers in a burger restaurant, we recommend following these steps:

1. Establish quality specifications

Define the standards expected from suppliers and the ingredients provided. These specifications should include detailed information on quality requirements, size, freshness, and other important characteristics.

2. Careful selection of suppliers

Work exclusively with reliable and responsible suppliers who care about the quality of their products. Conduct prior research to ensure that suppliers have the necessary permits and certifications.

3. Inspection of raw materials

It is important to carefully inspect each shipment of raw materials received from suppliers to ensure that it meets the previously established quality specifications. Quality tests can be carried out on-site and samples can be taken for laboratory analysis if necessary.

4. Establish appropriate storage processes

Store ingredients properly to guarantee their quality and freshness. This may include using specific temperatures, humidity conditions, appropriate packaging, and labelling.

5. Conduct regular audits

Regular audits should be carried out on suppliers to ensure they comply with the established quality standards. Performance indicators can be established to measure supplier performance and corrective actions can be taken in case of non-compliance.

6. Train staff on food safety in burger restaurants

It is important to train burger restaurant staff on ingredient quality standards and how to recognise quality problems. Staff should be trained to take appropriate quality control measures and report any problems to supervisors.

7. Follow regulations and standards

It is important to follow all regulations and standards related to food safety and food handling to ensure the quality and safety of products.

How should food be stored in a burger restaurant to prevent contamination?

Proper food storage in a burger restaurant is crucial to preventing contamination and maintaining food safety.

Here are some guidelines for storing food properly:

Separate storage

It is important to store different types of food separately to prevent cross-contamination. Raw foods, such as meat and poultry, should be stored separately from cooked foods and fresh produce, such as fruits and vegetables.

Correct temperature

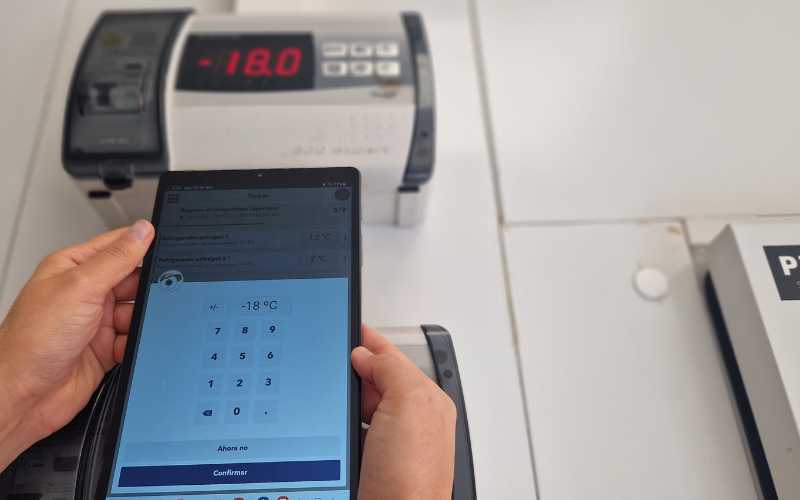

Food should be stored at safe temperatures to prevent the growth of bacteria and other microorganisms. Refrigerated food should be stored at 4°C or below, while frozen food should be stored at -18°C or below.

Proper storage of raw foods

Raw foods should be stored at the bottom of the refrigerator to prevent contamination of other foods. Additionally, they should be placed in containers with lids to prevent them from dripping onto other foods.

Food rotation

It is important to rotate food to use older products first and prevent them from expiring or spoiling.

Cleaning and sanitising

Shelves, containers, and other storage utensils should be cleaned and sanitised regularly to prevent the accumulation of bacteria and other microorganisms.

Proper storage of dry foods

Dry foods, such as flour, sugar, and breadcrumbs, should be stored in closed containers to prevent contamination.

Labelling

All foods should be labelled with the receiving date and expiration date to ensure they are used within the recommended time frame.

How Should Food Be Handled in Burger Restaurants to Prevent Contamination

Here are some important guidelines that should be followed when handling food in a burger restaurant:

Wash your hands: t is important to wash your hands frequently, especially after handling raw food, before handling cooked food, and after touching any object or surface that is not related to food preparation.

Proper storage: Raw food should be stored separately from cooked food to prevent cross-contamination. Additionally, all food should be stored at safe temperatures to prevent bacterial growth.

Proper handling: It is important to handle food properly to avoid contamination. This includes using clean and sanitized utensils, avoiding coughing or sneezing on food, and not using the same cutting boards for raw and cooked food.

Proper cooking: All food should be cooked to safe temperatures to ensure that it is fully cooked and safe to eat. Hamburgers should be cooked to an internal temperature of at least 71°C.

Personal hygiene: It is important that food handlers wear clean and appropriate clothing, including hats and disposable gloves.

HACCP measures for burger restaurants

As you well know, the Hazard Analysis and Critical Control Points (HACCP) system is a preventive food safety management system used to identify and control significant food safety hazards at each stage of the food production process.

While every country applies HACCP protocols differently, the following measures are key to food safety in burger restaurants:

Hazard Identification: The burger restaurant must identify physical, chemical, and biological hazards at each stage of the food production process, from receiving raw materials to serving food.

Identification of Critical Control Points (CCPs): The restaurant must identify CCPs where identified hazards can be controlled or prevented. Some CCPs may include receiving raw materials, food preparation, storage, and distribution.

Determining Critical Limits: The burger restaurant must establish critical limits for each CCP. Critical limits are the maximum and minimum values that must be met to ensure food safety.

Monitoring Food Safety in Burger Restaurants: The burger restaurant must monitor CCPs to ensure that critical limits are being met. Monitoring can be physical, chemical, or microbiological, depending on the hazard identified.

Corrective Actions: If a CCP is found to be not meeting critical limits, the burger restaurant must take corrective action to prevent food safety risks. These actions may include withdrawing the product, modifying the production process, or re-evaluating the CCPs.

Verification: The burger restaurant must verify that the HACCP system is being implemented correctly and that food safety objectives are being met. Verification may include additional food testing and analysis.

Documentation: The burger restaurant must document all stages of the HACCP system, including hazard identification, CCPs, critical limits, monitoring, and corrective actions taken.

Implementing a HACCP system can help your burger restaurant prevent significant food safety hazards and improve the quality of your products. It is important to have trained and experienced staff in the design and implementation of a HACCP system to ensure its success.

Food Safety in Burger Restaurants: The case of Berty’s Burger

Berty’s Burgers is leading the burger revolution in northern Spain with their explosive hamburgers.

Why explosive?

Their flambéed hamburgers are an explosion of flavours from the exquisite matured meat of Galician blonde cows, cooked in a josper – a special oven that cooks them on the grill and literally makes them melt in your mouth.

Their Dry Aged hamburger was awarded the second-best hamburger in Spain in 2022!

Berty’s Burger uses top-quality ingredients, techniques that enhance the flavor of the product, and relies on Andy to guarantee food safety in all its cooking processes.

How are hamburgers prepared and how long are they cooked to ensure they are fully cooked?

The Spanish Food Safety and Nutrition Agency (AESAN) recommends cooking hamburgers to an internal temperature of at least 71°C to destroy any bacteria that may be present in the meat.

While there isn’t one single international agency dictating global burger cooking temperatures, several renowned organisations provide international guidelines:

- World Health Organization (WHO): Their “Five Keys to Safer Food” campaign recommends cooking minced meat (including burgers) to an internal temperature of 70°C to kill harmful bacteria.

- Food and Agriculture Organization (FAO): Their “Codex Alimentarius” recommends a minimum internal temperature of 70°C for minced meat products.

- United States Department of Agriculture (USDA): They recommend cooking ground beef patties to an internal temperature of 160°F (71.1°C) for safety.

- European Food Safety Authority (EFSA): They suggest a minimum internal temperature of 70°C for minced meat preparations based on scientific evidence.

While there’s some minor variation in the specific temperature, all these reputable bodies emphasise reaching an internal temperature above 70°C to ensure food safety from potential bacteria like E. coli.

Ultimately, the specific temperature guideline to follow might depend on local regulations and individual risk tolerance. However, aiming for an internal temperature exceeding 70°C aligns with international best practices for safe burger consumption.

What food safety measures should a burger restaurant take to prevent foodborne illness?

Nerea Cristófalo, Food Technology Consultant at Andy, recommends following these steps to ensure the safe preparation of hamburgers in your kitchens:

1. Cleaning and Sanitising

All areas of the burger restaurant, including the kitchen, utensils, equipment, and bathrooms, should be cleaned and sanitized regularly to prevent the spread of bacteria.

2. Proper Food Handling

All food should be handled properly to avoid cross-contamination. Raw food should be stored separately from cooked food, and different utensils and cutting boards should be used to handle raw and cooked food.

3. Proper Food Storage

Food should be stored at proper temperatures to prevent bacterial growth. Raw food should be stored in separate areas from cooked food.

4. Cooking Properly

All food, including hamburgers, should be cooked to safe temperatures to ensure that they are fully cooked and safe to eat.

5. Personal Hygiene

Food handlers must follow proper personal hygiene practices, such as washing their hands regularly and wearing clean, appropriate clothing.

6. Staff Training

All employees of the burger restaurant should receive adequate training on food safety and food handling practices.

7. Regular Audits and Inspections

The burger restaurant should undergo regular internal audits and inspections by public health authorities to ensure that food safety standards are met and any potential problems are detected and corrected.

What types of health inspections are carried out in a burger restaurant?

Again, the frequency and focus of health inspections by public health authorities will vary from country to country (and possible from region to region), but most inspections will look into the following to ensure compliance and overall food safety in burger restaurants:

Algunos de los aspectos de la seguridad alimentaria en hamburgueserias que se evalúan durante estas inspecciones pueden incluir:

- Hygiene of the facilities and kitchen equipment.

- Cleanliness of the burger restaurant, including the dining area and bathrooms.

- Temperature control of stored and cooked food.

- Control of the expiration date of food.

- Proper food handling and prevention of cross-contamination.

- Food safety training for staff.

- Registration of products and their origin.

- Storage of cleaning products out of reach of food.

- Protection of food from possible insects, rodents, and other animals.

Failure to comply with food safety regulations can result in fines and temporary closure of the burger restaurant until the problems are resolved.

That’s why is so important for burger restaurants to comply with the requirements and undergo regular health inspections to ensure the food safety of their customers.

What precautions should be taken in a burger restaurant to prevent food allergies?

Some general important measures to follow to prevent food allergies in a burger restaurant include:

Informing the client: Burger restaurants must inform customers about the ingredients and allergens present in their products. This can be done through menus, posters, or brochures.

Training staff: Burger restaurant staff must be trained to answer questions about the ingredients and allergens present in the products and to know how to handle situations where a customer has a food allergy.

Identifying allergens: Ingredients that contain allergens, such as gluten, milk, or nuts, must be identified and labeled correctly. They should also be stored separately to avoid cross-contamination.

Preparing food separately: When preparing food for customers with food allergies, it should be prepared separately to avoid cross-contamination.

Proper cleaning and sanitising: All utensils, equipment, and work surfaces must be cleaned and sanitized properly to avoid cross-contamination.

Following food safety regulations: Burger restaurants must follow food safety and food handling regulations to prevent cross-contamination and ensure the safety of customers with food allergies.

Offering allergen-free options: Burger restaurants can also offer allergen-free options for their customers, such as vegetarian or vegan burgers, to ensure that all customers can enjoy a safe and satisfying meal.

How do you guarantee the food safety of a hamburger while being delivered?

To guarantee the food safety of a hamburger in delivery, certain measures must be followed to avoid contamination and maintain the quality of the product during transport.

Some of these measures are:

1. Proper packaging: The hamburger should be packaged in a safe and airtight container to prevent contamination by external agents and to maintain the proper temperature.

2. Use of thermal bags: The use of thermal bags is recommended to keep the hamburger hot during transport.

3. Delivery time: The delivery time should be as short as possible to prevent the hamburger from cooling and becoming contaminated.

4. Clear labelling: The package should be clearly labelled with the product name, date of manufacture, and expiration date.

5. Contactless delivery: Contactless delivery is recommended to avoid physical contact and reduce the risk of contagion.

6. Trained personnel: The personnel who handle and deliver the hamburger must be trained in hygiene and food safety practices, and follow the contagion prevention protocols.

7. Quality verification: The customer must verify the quality of the product at the time of delivery, and in case of finding any problem, report it immediately to the establishment.

These measures will help guarantee the food safety of a hamburger in delivery and ensure customer satisfaction.

Food safety in burger restaurants: How do you train your teams?

Employees must be properly trained in food safety to guarantee the quality and safety of the brand’s products.

Here are some general guidelines that can be followed to train employees on food safety:

Specific food safety training in burger restaurants

Provide employees with adequate food safety training that includes the following topics: personal hygiene, food temperature control, prevention of cross-contamination, proper food handling, and cleaning and sanitising of facilities and kitchen utensils.

Food safety manuals

Make food safety manuals available to employees describing the burger restaurant’s food safety policies and procedures.

Food safety practices

Teach employees to follow food safety practices, such as: washing hands before and after handling food, wearing gloves and kitchen hats, storing food properly, and avoiding cross-contamination.

Supervision and monitoring

Supervise employees and ensure that they are following food safety procedures correctly. It is also important to conduct regular follow-ups to ensure that employees are complying with food safety regulations.

Constant updating

Make sure that employees are updated on the latest food safety regulations and regulations to ensure that they are following the proper practices.

Reinforcement of the importance of food safety

Reinforce the importance of food safety and its impact on the health of customers and the reputation of the burger restaurant.

Properly training employees on food safety is essential to ensure the quality and safety of burger restaurant products and to avoid public health problems.

Food safety in burger restaurants: how does technology help?

In one single word: Infinitely!

Andy will help you meet, improve and perfect your operational goals, improve productivity, save costs and time, and above all protect the health of your customers and the reputation of your burger restaurant.

Andy is a leading food safety digital assistant for the foodservice, acting as another team member in commercial kitchens everywhere, thinking and intelligently guiding the rest of the team.

Andy works hand in hand with other team members, facilitating their actions and tasks to be carried out so that your food safety processes are correctly implemented at all times.

Major foodservice brands trust Andy from Domino’s Pizza, to NewRest, Starbucks and many others!

Many of them are large international companies that use Andy to guide “teams” in their food safety tasks in a friendly and intelligent way, preventing incidents and ensuring that quality work is done in the shortest possible time.

Andy digitises all the actions relevant to food safety processes, traceability, labelling and hygiene of the workplace, considerably reducing the time that the team dedicates to them, and facilitating the perfect compliance of all the records of HACCP, Hygiene, labelling, etc.

The following are some of the tasks with which Andy helps to keep burger restaurant kitchens free of risks for the consumer:

1. Digital HACCP

Andy digitises cleaning and hygiene records, maintenance, temperatures and any necessary checklist, ensuring that they are always in compliance with the law.

Thanks to the digitisation of HACCP with Andy, it is possible to comply with all the mandatory records while activating corrective plans automatically, streamlining operations – from taking temperatures to implementing corrective actions, establishing acceptable limits and monitoring frequency.

As explained in this article, with Andy you can rest assured that your employees will never miss a temperature control point!

And not only that, right now, restaurants that already work with Andy are also measuring another very important metric: the internal temperature of cooked and reheated food.

Our “partners” use Andy to control the first foods made in the morning shift and the first made in the night shift.

They take the temperature of a product from each piece of equipment (fryer, oven, bain-marie, etc.), and even from the microwave (reheating).

To do this, they unify the temperature of the Critical Control Point to >=65ºC.

In this way they ensure that the food has exceeded the critical limit and verify the correct functioning of the machinery.

Through (previously appropriately configured) Action Plans, Andy guides teams at all times so they always know what to do.

And that means zero risks caused by the many human errors that can understandably be made when the kitchen turns into a pressure cooker!

👉Find out more about digital HACCP with Andy👈

2. Food labelling

Our efficient fast food restaurant operations software also has the ability to label products and ingredients much faster and easier, ensuring greater food safety in all types of kitchens.

In fact, in this article we prove that automatic expiry date labelling is at least twice as fast as the cumbersome manual labelling.

When you don’t automate the labelling processes of expiry dates in your burger restaurants you are losing hours worked invested in repetitive tasks that result in employee burn out…

And that means wasted salaries and talents.

Continuing with manual expiry date labelling means continuing to work with errors that cost time and money.

It means incorrectly labelled food that ends up being wasted.

And it means questionable traceability processes that can negatively impact the reputation and finances of your brand.

👉Learn about efficient food labelling with Andy👈

3. Incident Management

Andy automates any incident that occurs in a commercial kitchen with simple and effective corrective plans.

Andy has the power to help resolve non-conformities and activate the correct action plan to address in a fraction of the time that kitchen teams typically spend, ideal for ensuring food safety in all types of restaurants.

What happens when there is a food emergency at your burger restaurant?

- Andy reacts quickly to a machinery incident

- Resolves the incident with maximum agility and minimum stress

- Monitors the status of the incident

- Recognises incidents and knows how to react

- Coordinates with the person or company that must resolve the incident

- Follows up on an incident from outside the restaurant.

What are the benefits of automated incident control with Andy for you?

- Reduced reaction time to an incident

- Reduced number of incidents on the premises

- Reduced time to manage an incident

- Increased HQ’s knowledge of incidents

- Reduced time between an incident occurring and HQ reacting.

- Reduced bureaucracy involved in dealing with an incident.

- You demonstrate that HQ reacts quickly to needs in the premises

- Longer useful life of the machinery

- Incidents that are not resolved are prevented

- Greater supervision of incidents

- Faster reaction time to an incident

- Better coordination between people when resolving an incident

And not only that.

With Andy, training on incident management and food alerts is a much simpler process, as you can easily demonstrate how to manage them with clear and real examples.

What happens when there are fewer incidents and problems in your burger restaurant/s?

You create a much happier work environment and a team that is proud to belong, avoiding the much-feared staff turnover.

👉Find out more about managing incidents with Andy👈

In addition, Andy can help you with the following specific food safety processes in burger restaurants as it does in so many kitchens that already trust our digital assistant:

- Food safety auditing

- Labelling of ingredients in detail, including vegetables, sauces, desserts, meat, bread and cheeses.

- Control of product manufacturing temperatures.

- Daily control of the oil renewal record for each of the fryers.

- Daily control of chlorine levels in the water.

- Organisation of cleaning tasks in daily, weekly, fortnightly and monthly protocols.

- Record to keep the list of suppliers up to date.

- Registration of receipt of raw materials and exhaustive control of meat traceability.

- Training record where the training given to workers is kept.

So, if you are embarking on a new business venture, make sure you integrate Andy into your kitchens to guarantee food safety in your burger restaurant!

Try now the many advantages that Andy can deliver to all types of restaurants for free for 10 days!