Barriers to Adopting a Digital HACCP System and How to Overcome Them

Managing HACCP (Hazard Analysis and Critical Control Points) manually can feel a bit like trying to juggle eggs—one small misstep and the whole thing comes crashing down. 😅

Manual HACCP management is prone to human error, inconsistent record-keeping, and missed critical checks, especially in larger operations or multi-site businesses where it feels like you’re always playing catch-up.

These pain points not only put compliance at risk but also increase the chance of food safety issues slipping through the cracks. And let’s face it: when it comes to food safety, even the smallest slip-up can have big consequences.

Despite these challenges, many business owners hesitate to adopt digital HACCP solutions.

Why?

Because the transition to a digital system can feel daunting, with common concerns such as high implementation costs, the complexity of new technologies, and potential downtime during setup.

But the reality is, while these concerns are natural, they can be overcome with the right strategy, and the benefits of a digital HACCP system far outweigh the initial challenges.

In this post, we’ll discuss how digital HACCP works, explore its benefits, and address the common barriers to implementation head-on, drawing from the experiences of clients who have successfully transitioned with Andy.

What is a Digital HACCP System?

Digital HACCP replaces the traditional pen-and-paper approach with smart technology, allowing businesses to automate and streamline their HACCP processes in real-time.

It focuses on identifying critical points in the food production process where risks like contamination or improper handling may occur.

The goal is to establish procedures and checks at these points to ensure food safety from farm to fork.

Traditionally, HACCP has been managed using manual, paper-based systems that involve logging temperatures, monitoring storage, and keeping detailed records to comply with regulations. While effective, manual systems are labor-intensive and prone to human error, which can lead to lapses in safety and compliance.

Many countries now encourage or require businesses to adopt digital food safety systems to ensure compliance.

While HACCP is globally recognised, some regions have adapted their own versions to meet local regulations.

A digital HACCP system transforms manual processes by replacing paper logs with technology that automates, monitors, and records each step of the HACCP plan in real-time.

Instead of manually tracking data, digital systems rely on sensors, software, and cloud-based platforms to monitor critical control points (CCPs) like temperature, storage conditions, and hygiene practices.

The CONS of Manual HACCP Management

Managing HACCP manually presents a variety of challenges that can hinder the effectiveness and efficiency of food safety management.

Although many businesses rely on manual HACCP processes, these systems are prone to human error and inefficiency, especially in larger or more complex operations. Below are some of the key problems associated with manual HACCP management:

1. Time-Consuming and Labor-Intensive

Manual HACCP systems involve logging every critical control point (CCP) by hand, which is a slow and repetitive task.

Recording temperatures, checking storage conditions, and tracking corrective actions can take up valuable time that staff could be spending on higher-value tasks, such as improving food quality or service.

Moreover, gathering all this paperwork for audits is extremely laborious, as managers often need to comb through large amounts of records to prepare for inspections.

2. Human Error and Inconsistencies

One of the biggest downsides of manual management is the potential for human error.

Employees can forget to log critical data, make mistakes when inputting information, or skip steps in the HACCP plan altogether. For instance, an employee might forget to record a temperature at a critical point, or the recorded data may be inaccurate due to misreadings.

Over time, these small errors add up, potentially leading to serious food safety violations or health hazards.

3. Inconsistent Record-Keeping

Maintaining consistent and thorough documentation is a cornerstone of HACCP.

However, in busy kitchens or food processing environments, this is easier said than done!

Record-keeping can become inconsistent, with some data missing or incomplete, especially during peak hours when employees are juggling multiple responsibilities. This inconsistency can undermine the integrity of the HACCP system and leave businesses exposed to compliance risks.

4. Difficulty with Audits and Traceability

One of the key requirements of HACCP is the ability to trace food safety issues back to their source.

When records are scattered across different paper forms or notebooks, it becomes challenging to track down the information needed for audits or during food safety incidents.

Auditors may request specific logs or records that, if not properly maintained or organized, can take hours to locate. This inefficiency increases stress during audits and risks non-compliance.

5. Lack of Real-Time Monitoring

Manual HACCP systems lack the ability to monitor critical points in real-time, which can delay the detection of food safety hazards. For example, if a refrigeration unit fails in the middle of the night, manual logs won’t capture the issue until the next morning. By then, the safety of the food may already be compromised.

Without real-time alerts, businesses are more vulnerable to undetected issues that could lead to foodborne illness outbreaks or financial losses.

6. Limited Scalability

As a business grows or expands to multiple locations, managing HACCP manually becomes increasingly difficult. Each location may have its own procedures, staff, and methods for documenting HACCP compliance, leading to inconsistencies across the business.

Scaling manual HACCP systems to accommodate multiple sites can quickly overwhelm managers, making it nearly impossible to ensure consistency and compliance across all operations.

7. Compliance Risks

With manual systems, there’s a greater risk of non-compliance with food safety regulations. Missed documentation, forgotten checks, or incorrect data entries can lead to violations during health inspections.

Failure to comply with HACCP requirements can result in fines, penalties, and reputational damage, as well as a higher likelihood of foodborne illness outbreaks.

8. Training Challenges

Training staff on manual HACCP procedures can be complex and time-consuming, especially in environments with high employee turnover. Every new hire needs to be taught how to properly record data and adhere to the HACCP plan, which requires ongoing supervision and retraining. Even with training, new employees may struggle to remember every step, leading to inconsistencies in how HACCP tasks are performed.

9. Difficulties with Corrective Actions

When a critical control point fails, it’s essential to take corrective action immediately. However, in manual systems, identifying and documenting these failures can be slow, meaning that corrective actions may be delayed. This can increase the risk of serving unsafe food, leading to potential outbreaks, recalls, or fines.

10. Environmental Impact

Manual HACCP systems often involve large amounts of paper, which adds to waste and can be inefficient from a sustainability perspective. As businesses increasingly adopt more sustainable practices, the environmental impact of a paper-heavy HACCP system becomes an additional concern.

The PROS of Digital HACCP management

Digital HACCP transforms this process by replacing paper logs with technology that automates, monitors, and records each step of the HACCP plan in real-time. Instead of manually tracking data, a digital HACCP system relies on sensors, software, and cloud-based platforms to monitor critical control points (CCPs) like temperature, storage conditions, and hygiene practices.

Switching to a digital HACCP system, like Andy, provides a wealth of advantages beyond just streamlining food safety management.

Here’s an expanded look at the key benefits of going digital:

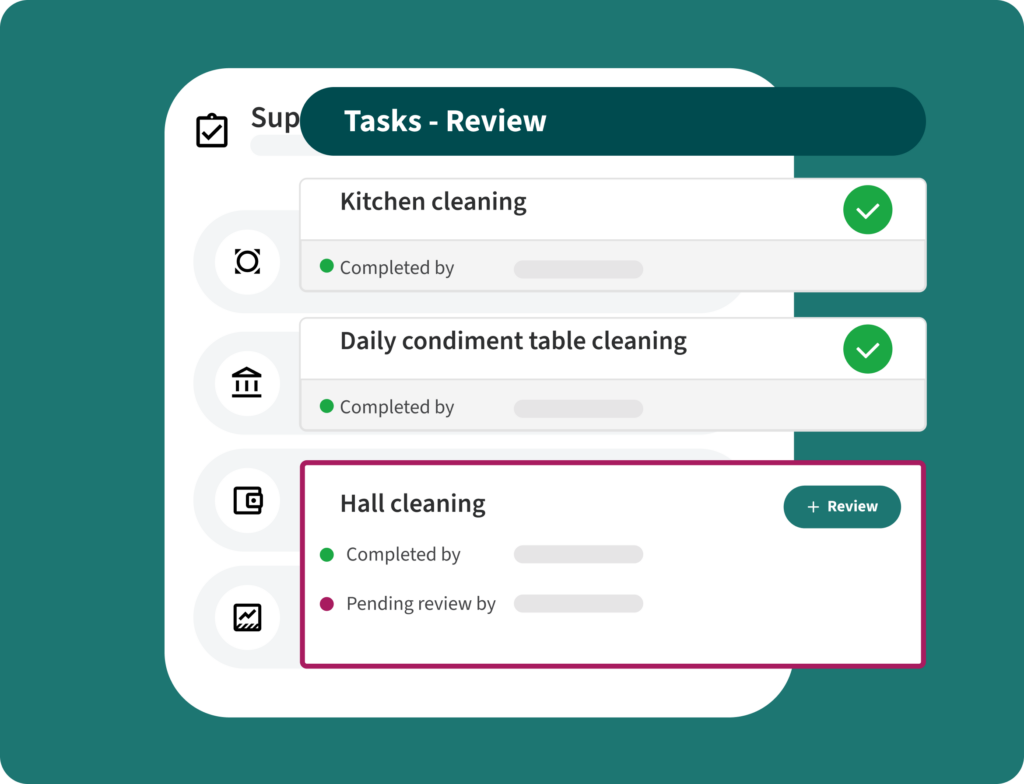

1. Increased Efficiency

Managing food safety manually requires significant time and effort. Tasks like temperature monitoring, tracking CCPs, and logging corrective actions consume valuable staff time.

With a digital system, these processes are automated, freeing up employees to focus on more important operational or customer-facing tasks.

By automating these repetitive tasks, you not only speed up operations but also ensure that checks are completed consistently and in real-time.

2. Improved Accuracy and Reduced Human Error

Human error is inevitable in any manual system, especially in a fast-paced food service environment. A digital HACCP system helps reduce these mistakes by automatically recording data and ensuring the accuracy of critical safety information, such as temperature logs or expiration dates. Automated alerts can remind staff of necessary actions, such as when a CCP reaches a critical limit, thus minimising the risk of oversight.

This guarantees that the system is error-proof, and safety data is captured consistently without gaps.

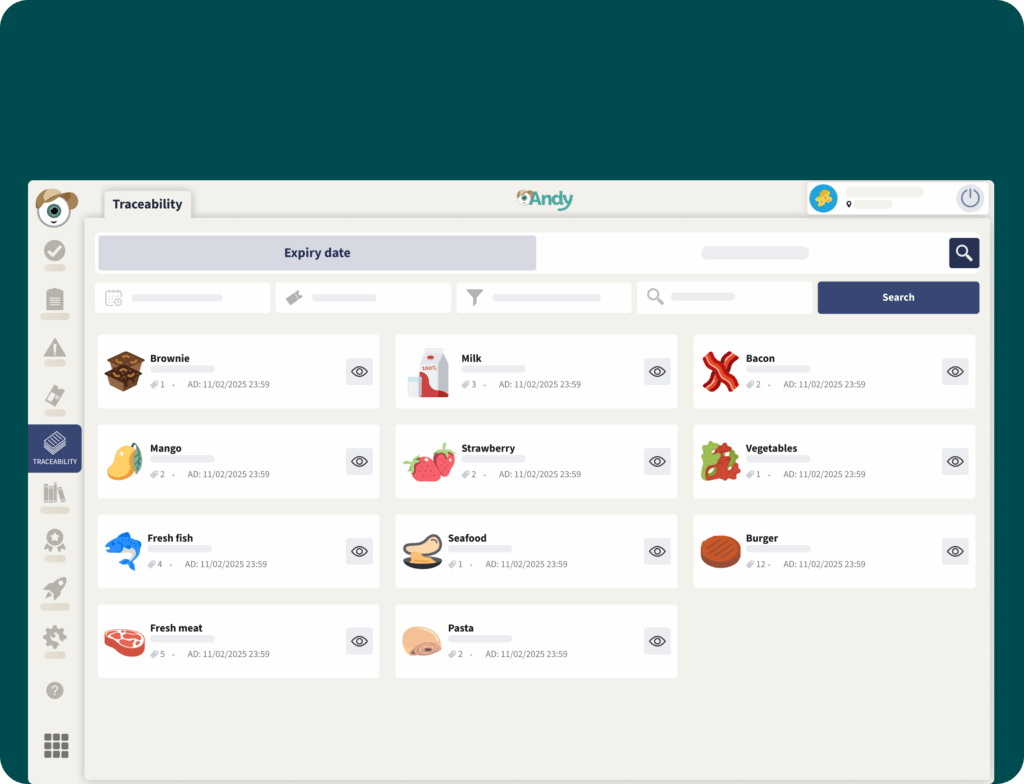

3. Faster Audits and Simplified Traceability

One of the biggest pain points for many food safety managers is the preparation for audits. Sifting through piles of paperwork is time-consuming and stressful. With digital HACCP, records are stored centrally and can be accessed instantly. This not only speeds up the audit process but also makes it far easier to trace back any issues to their source, whether it’s a supplier, batch of ingredients, or a particular CCP failure.

In the event of a recall, the ability to quickly identify the problem and take corrective action can be a lifesaver, both for the business and its reputation.

4. Enhanced Compliance and Risk Management

Compliance with food safety regulations is critical for avoiding penalties, but keeping track of every procedure manually can be overwhelming. Digital HACCP systems like Andy can be programmed to align with specific regulatory requirements.

Automatic alerts ensure that tasks are completed on time, like temperature checks or cleaning schedules, helping businesses avoid violations during inspections.

Furthermore, having real-time data enables better decision-making and risk management, as you’re always aware of your compliance status.

5. Cost Reduction with digital HACCP

The upfront investment in a digital HACCP system is quickly offset by long-term savings. By automating processes, you reduce labor costs associated with manual data entry, verification, and audits. More accurate record-keeping also means less food waste, as expiration dates and storage temperatures are carefully monitored and maintained.

Additionally, the reduction in human error minimises the risk of costly food safety violations, product recalls, or penalties, saving your business from financial and reputational damage.

6. Enhanced Productivity and Staff Empowerment

A digital HACCP system lightens the administrative burden on staff. By automating the tedious parts of food safety management, employees are empowered to focus on more strategic and high-value tasks, such as food preparation, customer service, or overall process improvement.

The intuitive interfaces of modern systems like Andy also simplify training and onboarding, so new employees can quickly learn how to manage food safety protocols.

7. Real-Time Monitoring and Insights

One major advantage of digital HACCP systems is the ability to monitor operations in real-time. Whether it’s temperature control in refrigeration units or tracking CCPs during food preparation, digital systems provide live updates.

This allows managers to respond quickly to potential hazards before they escalate, improving food safety outcomes. Additionally, many systems generate reports that provide insights into trends, allowing you to proactively address recurring issues or inefficiencies.

8. Sustainability and Environmental Impact

By switching to digital HACCP, your business reduces its reliance on paper-based documentation, contributing to more sustainable practices.

Furthermore, the ability to reduce food waste by managing inventory and expiration dates more effectively also has a positive impact on your environmental footprint.

9. Scalability for Growing Businesses

For food businesses looking to expand, manual HACCP processes become increasingly difficult to manage.

As operations grow, more CCPs need to be monitored, and keeping track of them manually across multiple locations is unsustainable. Digital systems like Andy are easily scalable, allowing businesses to maintain consistency and compliance even as they expand.

By adopting a digital HACCP system, businesses not only ensure better food safety compliance but also enjoy operational efficiencies, cost savings, and greater peace of mind.

What Are the Barriers to Adopting a Digital HACCP System?

While the benefits of digital HACCP systems like Andy are clear—improved efficiency, accuracy, and compliance—there are still common concerns that cause hesitation for many businesses.

Based on feedback from Andy’s clients and industry observations, these barriers often include the following:

1. Initial Cost of Implementation of digital HACCP

One of the most frequent concerns is the upfront cost of adopting a digital HACCP system.

For small to medium-sized businesses, investing in new technology, including hardware like sensors or label printers and software licenses, can seem like a significant financial commitment. The perception is that the initial investment might not immediately offset the costs associated with maintaining a manual system, especially in businesses operating with tight margins.

Overcoming This Barrier:

The initial digital HACCP costs should be seen as an investment rather than an expense.

Andy offers flexible pricing models to suit different business sizes.

Additionally, the long-term savings gained through reduced labour costs, improved compliance, fewer food safety incidents, and minimised waste far outweigh the initial expense.

Businesses also tend to save on the hidden costs of non-compliance, which can include fines, food recalls, and reputational damage.

2. Resistance to Change

Even with potential benefits, teams who are used to manual systems often resist moving to a digital HACCP solution.

Employees may feel that the traditional methods they are familiar with work “well enough,” and transitioning to a new system can feel like an unnecessary disruption. This hesitation often stems from concerns about increased complexity or fear of additional workload.

Overcoming This Barrier:

To address resistance, it’s important to focus on user-friendly digital tools.

Andy’s platform is designed with simplicity in mind, offering intuitive dashboards and step-by-step processes that are easy for staff to follow.

Involving key team members in the decision-making and implementation process can also ease the transition, as they will feel more engaged and see firsthand how the new system simplifies their work, rather than complicating it.

3. Learning Curve

Another common barrier is the learning curve associated with adopting new technology. Staff members who are not tech-savvy may feel intimidated by the idea of learning a new system, especially if they’ve been using manual processes for years. There’s often a perception that learning and adapting to digital tools will require extensive training and disrupt day-to-day operations.

Overcoming This Barrier:

Digital HACCP systems like Andy are designed to be as user-friendly as possible. In fact, Andy’s implementation includes training sessions that are tailored to the team’s needs, ensuring that even non-technical staff can quickly understand and navigate the platform. Additionally, ongoing support is often provided, making sure users have help when they need it.

The time investment for learning digital systems is often much shorter than expected, and once teams become familiar with the system, they experience much faster workflows and reduced manual effort.

4. Perceived Time Investment for Setup

Many businesses fear that transitioning to a digital HACCP system will take too much time and effort, especially during the setup phase. There’s a perception that installing sensors, uploading compliance records, and training staff will result in lost productivity or downtime.

Overcoming This Barrier:

While setting up a digital HACCP system does require some initial time investment, it doesn’t need to be overly disruptive. For example, Andy’s platform allows for seamless integration into existing workflows with minimal setup time. The team behind Andy provides hands-on support during implementation to minimise disruption, and most businesses find that the long-term time savings far outweigh the brief setup period.

5. Data Security Concerns

With the rise of cloud-based systems, some clients worry about the security of storing sensitive food safety data online. Fear of data breaches, unauthorised access, or loss of records can prevent some businesses from fully embracing digital solutions.

Overcoming This Barrier:

Data security is a legitimate concern, but modern digital HACCP platforms like Andy use robust encryption and secure cloud storage to protect sensitive information.

Many platforms comply with industry-standard security measures, ensuring that your data is as safe—or safer—than it would be with manual, paper-based systems. Additionally, cloud-based solutions offer the benefit of automatic backups, so critical information is never lost, even if physical systems fail.

By addressing these common concerns and emphasising the long-term benefits, businesses can move past these barriers and embrace the efficiency, safety, and compliance that digital HACCP systems bring to the table.

While the transition from manual to digital HACCP may seem daunting, the long-term benefits far outweigh the challenges.

Andy will not only streamline food safety management in your professional kitchen/s but it will also offer a more efficient, cost-effective way to ensure compliance and improve overall operations while staying environmentally and people smart!