7 Common Operational Mistakes Food Service Kitchens Must Avoid in 2025

As we enter a new year, the food service industry faces an era of heightened expectations and challenges. Operational efficiency in food service kitchens is no longer a nice-to-have – it’s a cornerstone for survival and success in an increasingly competitive landscape.

Kitchens are under pressure to consistently deliver on safety, quality, and customer satisfaction, all while managing rising costs, stricter regulatory demands, and the constant need for innovation.

Achieving operational excellence in food service kitchens requires more than just meeting baseline requirements; it involves cultivating precision, adaptability, and a commitment to continuous improvement.

However, even the most well-run kitchens are vulnerable to common pitfalls that can disrupt workflows, inflate costs, and jeopardise compliance.

Identifying and addressing these operational missteps is crucial for food service businesses to thrive.

In this article, we explore seven critical mistakes that food service kitchens must avoid in 2025.

Each point looks into the root causes of inefficiency and offers practical solutions to ensure your operations run seamlessly, setting the foundation for a successful year ahead.

Whether you’re managing a high-volume commercial kitchen or a boutique dining operation, these insights will help you stay ahead of the curve and deliver an exceptional experience to every customer.

7 Common Operational Mistakes Food Service Kitchens Must Avoid in 2025

1/ Inconsistent Recipe Execution

The Mistake

Variations in recipe execution are a common operational problem that can compromise the quality and consistency of dishes.

Inconsistent measurements, incorrect cooking times, and deviations from standard procedures often lead to food that doesn’t meet customer expectations, ultimately harming brand reputation.

Why It’s Important:

- Customer Retention: Research shows that 68% of customers are unlikely to return to a restaurant after a negative food experience. Consistency in taste and presentation is key to building trust and loyalty.

- Brand Identity: For chain or multi-location restaurants, inconsistencies dilute the brand identity. A customer should receive the same experience, regardless of the location they visit.

- Operational Efficiency: Inconsistent execution can lead to waste, rework, and increased costs as teams struggle to recreate the intended dish.

The Fix:

1/ Standardised Recipes:

-

- Develop and document detailed recipes that include precise measurements, preparation techniques, and plating instructions.

- Use recipe management software to ensure all team members can access the most up-to-date versions across multiple locations.

- Ingredient Control:

- Pre-portion ingredients to ensure consistency and reduce preparation time.

- Use digital scales and tools for precise measurements to eliminate guesswork.

2/ Training Programs:

Train all staff on the importance of following recipes exactly, especially during onboarding and when introducing new menu items.

Conduct regular skill assessments to ensure adherence to standards.

3/ Automation and Technology:

Implement kitchen display systems (KDS) that guide chefs through each step of preparation. These systems can include timers, step-by-step instructions, and visuals for plating.

For high-volume operations, consider automated tools like portioning devices and cooking equipment programmed for specific recipes.

4/ Quality Checks:

Introduce regular quality control protocols, such as “spot checks” by senior kitchen staff or supervisors.

Encourage feedback from both the kitchen team and customers to identify recurring inconsistencies.

By investing in standardisation and leveraging technology, food service kitchens can maintain the consistency and quality that customers expect, ensuring a positive dining experience every time.

2/ Poor Food Labelling and Traceability

The Mistake

Failing to implement accurate food labelling and robust traceability systems can lead to compliance issues, operational inefficiencies, and potential food safety crises.

Mislabelled or unlabelled ingredients make it challenging to track food origins, monitor allergens, and address recalls effectively.

Why It’s Important:

- Allergen Management: According to the European Food Safety Authority (EFSA), 34% of food recalls in the EU are linked to undeclared allergens. Mismanaged labels pose significant risks to consumer health and brand reputation.

- Regulatory Compliance: In 2025, tighter regulations such as mandatory enhanced traceability under the EU Farm to Fork Strategy demand that kitchens track food origins and movements across the supply chain.

The Fix:

1/ Adopt Digital Traceability Tools: Invest in systems that automatically record and monitor food origins, batch details, and expiry dates. Digital solutions can integrate with inventory management to flag potential issues in real-time.

2/ Streamline Labelling Practices: Use technology to print detailed, accurate labels that include allergen information, production dates, and batch numbers. Automated systems minimise human error and speed up the process.

3/ Train Staff: Ensure all team members understand the importance of accurate labelling and traceability, especially when dealing with allergens and perishable goods.

4/ Leverage QR Codes for Transparency: QR codes on labels can provide additional product information to customers while allowing kitchens to quickly access traceability data during audits or recalls.

By prioritising food labelling and traceability, your kitchen can prevent costly mistakes, protect consumer health, and maintain compliance in an increasingly regulated landscape.

3/ Inefficient Workflows

The Mistake

Disorganised kitchen layouts and inefficient workflows create unnecessary bottlenecks in food service kitchens, slow down service times, and lead to increased employee stress.

Common symptoms include staff bumping into each other, tools being misplaced, and preparation tasks taking longer than necessary due to poor organization.

Why It’s Important:

- Time Savings: Kitchens that streamline workflows can reduce prep and cooking times by up to 25%, according to InfoHoreca. This means faster service, more table turns, and greater customer satisfaction.

- Order Accuracy: Streamlined workflows minimise miscommunication and errors during busy shifts, improving the consistency and quality of the final product.

- Employee Morale: A well-organised kitchen reduces stress and physical strain, resulting in better job performance and lower turnover.

The Fix:

1/ Conduct a Workflow Audit:

Map out each station’s activities to identify inefficiencies and overlaps.

Use tools like time-motion studies to understand how staff moves through the kitchen and adjust the layout accordingly.

2/ Optimise Layout:

Follow the “kitchen triangle” principle: position prep areas, cooking stations, and storage in a logical flow to minimise unnecessary movement.

Group tools and ingredients by task (e.g., all baking tools in one area) to reduce search time.

3/ Implement Clear Task Delegation:

Define and communicate roles for each team member during shifts.

Use kitchen display systems (KDS) to assign tasks and track progress in real-time.

4/ Invest in Ergonomic Design:

Install adjustable countertops, anti-fatigue mats, and well-placed storage to reduce strain on employees.

Ensure equipment placement allows for easy access and movement.

By redesigning workflows and layouts, kitchens can enhance productivity, improve service quality, and create a more harmonious work environment.

4/ Neglecting Maintenance of Equipment

The Mistake

Skipping routine maintenance can lead to unexpected equipment failures during peak service hours, causing delays, higher costs, and lost revenue.

Common culprits include refrigeration systems, ovens, and dishwashers that aren’t serviced regularly.

Why It’s Important:

- Downtime Costs: Studies show that unplanned downtime can cost restaurants thousands of dollars in lost sales per day.

- Service Speed: Equipment breakdowns slow down service, frustrate staff, and negatively impact the customer experience.

- Long-Term Savings: Preventive maintenance extends the lifespan of equipment, reducing the need for costly replacements.

The Fix:

1/ Create a Preventive Maintenance Schedule:

Set regular intervals for cleaning, calibrating, and inspecting equipment.

Include daily, weekly, and monthly checklists for tasks such as filter cleaning, lubrication, and part inspections.

2/ Use Digital Tools for Tracking:

Implement maintenance management software to set reminders, log repairs, and monitor equipment performance.

Track maintenance history to identify patterns and anticipate potential issues.

3/ Train Staff:

Teach kitchen staff to recognise warning signs like unusual noises or temperature fluctuations and report them immediately.

Empower employees to perform basic maintenance tasks, such as tightening bolts or replacing filters, to prevent larger problems.

4/ Partner with Reliable Technicians:

Establish relationships with service providers who specialise in commercial kitchen equipment for prompt repairs.

A proactive maintenance strategy ensures seamless operations, protects revenue, and avoids last-minute stress during service hours.

5/Inadequate Food Safety Monitoring

The Mistake

Relying on manual processes to monitor critical food safety parameters, such as temperature, hygiene, and sanitation, increases the risk of non-compliance and foodborne illnesses.

Why It’s Important:

- Regulatory Compliance: With stricter regulations from agencies like the FDA and EU Food Safety Authority, non-compliance can lead to heavy fines or closures.

- Reputation Management: A single food safety incident can damage brand trust and lead to costly legal issues.

- Efficiency: Manual monitoring is time-consuming and prone to human error, leading to inaccurate records.

The Fix:

1/ Adopt Real-Time Monitoring Systems:

Use IoT-enabled sensors to track temperature, humidity, and other critical parameters automatically.

Receive instant alerts for deviations, allowing immediate corrective action.

Replace paper-based records with digital logs that are easier to update, store, and retrieve.

Ensure compliance with audit requirements by generating reports instantly.

3/ Regular Audits and Inspections:

Conduct internal audits using digital tools to assess compliance with hygiene and safety protocols.

Address any non-conformities promptly with clear action plans.

4/ Invest in Staff Training:

Provide ongoing education on food safety practices, emphasising the importance of accurate monitoring.

Use training tools like gamified learning or role-playing scenarios to keep staff engaged.

By integrating automated monitoring and fostering a culture of accountability, food service kitchens can safeguard both their customers and their reputation in 2025 and beyond.

6/ Insufficient / Inadequate Staff Training

The Mistake

Overlooking the importance of ongoing training leaves employees ill-equipped to manage updated safety protocols, emerging technologies, and evolving customer expectations. This gap can result in errors, decreased efficiency, and customer dissatisfaction.

Why It’s Important:

- Improved Efficiency: Research shows that well-trained teams can reduce operational errors by up to 50%, enhancing both workflow efficiency and customer satisfaction.

- Adaptability: In 2025, the rapid adoption of digital tools and changing food safety regulations mean that staff must stay informed to perform effectively.

- Employee Retention: Investing in training boosts morale and loyalty, reducing turnover in a sector where high attrition is common.

The Fix:

1/ Develop a Structured Training Program:

Include hands-on sessions, e-learning modules, and video tutorials tailored to various aspects of operations, such as food safety, customer service, and the use of new technologies.

Integrate regular refreshers to reinforce knowledge and adapt to industry changes.

2/ Use Digital Tools:

Platforms like Andy can help you deliver scalable, interactive training that tracks employee progress and compliance.

Gamify learning to engage staff and encourage skill retention.

3/ Onboarding excellence:

Ensure new hires are thoroughly trained during their onboarding process. Emphasise key areas such as food safety, workplace procedures, and customer interaction from day one.

4/ Create a Feedback Loop:

Allow employees to evaluate training sessions and suggest improvements, ensuring the program remains relevant and impactful.

With a robust training program, food service kitchens can ensure their teams are confident, competent, and ready to excel in any situation.

7/ Lack of Adequate Self-Evaluation and Auditing

The Mistake

Failing to conduct regular self-evaluations and audits means missed opportunities to identify gaps in safety, efficiency, and compliance before they become serious issues.

Why It’s Important:

- Proactive Problem Solving: Self-audits help uncover inefficiencies, safety risks, and non-compliance, allowing corrective actions before external inspections occur.

- Regulatory Preparedness: In 2025, regulatory bodies are expected to increase scrutiny of food service establishments, making internal audits a critical part of compliance.

- Continuous Improvement: Regular evaluations foster a culture of accountability and encourage teams to strive for excellence.

The Fix:

1/ Implement Digital Audit Tools:

- Use platforms like Andy to automate and standardise self-evaluations. These tools streamline the auditing process, reduce paperwork, and provide actionable insights.

- Monitor real-time data to identify patterns and prioritise areas for improvement.

2/ Create Checklists and Protocols:

- Develop detailed audit checklists covering all aspects of operations, including food safety, inventory, and equipment maintenance.

- Customise checklists for specific kitchen areas or operational stages.

3/ Schedule Regular Reviews:

- Conduct weekly or monthly internal audits to ensure ongoing compliance and to track progress on previously identified issues.

- Assign dedicated team members or managers to lead the evaluations.

4/ Act on Findings:

- Use audit results to implement corrective actions and update procedures.

- Share findings with teams to reinforce the importance of compliance and continuous improvement.

Regular self-evaluations are a vital part of operational excellence, ensuring that kitchens stay proactive and prepared for any challenge.

8/ Lack of Sustainability Practices

The Mistake:

Failing to adopt eco-friendly practices alienates environmentally conscious customers, inflates costs, and contributes to environmental degradation.

Why It’s Important:

- Consumer Expectations: According to Apicbase, 39% of food service operators plan to prioritise sustainability in 2025, aligning with growing consumer demand for eco-conscious businesses.

- Cost Reduction: Practices such as waste minimisation and energy efficiency can lead to significant cost savings.

- Reputation Management: Sustainability is a key differentiator for brands looking to attract younger, environmentally aware customers.

The Fix:

1/ Minimise Food Waste:

- Use inventory management software to track usage patterns, reduce overordering, and optimise portion sizes.

- Donate excess food to local charities or repurpose ingredients creatively.

2/ Invest in Energy-Efficient Equipment:

- Upgrade to energy-efficient appliances and lighting to lower utility costs and reduce carbon footprints.

- Conduct energy audits to identify and address inefficiencies.

3/ Source Locally:

- Partner with local suppliers to reduce transportation emissions and support community economies.

- Highlight these efforts in marketing materials to build customer trust.

4/ Eco-Friendly Packaging:

- Switch to biodegradable, compostable, or reusable packaging to meet consumer preferences and reduce waste.

- By integrating sustainability into daily operations, food service kitchens can reduce costs, meet customer expectations, and contribute to a healthier planet.

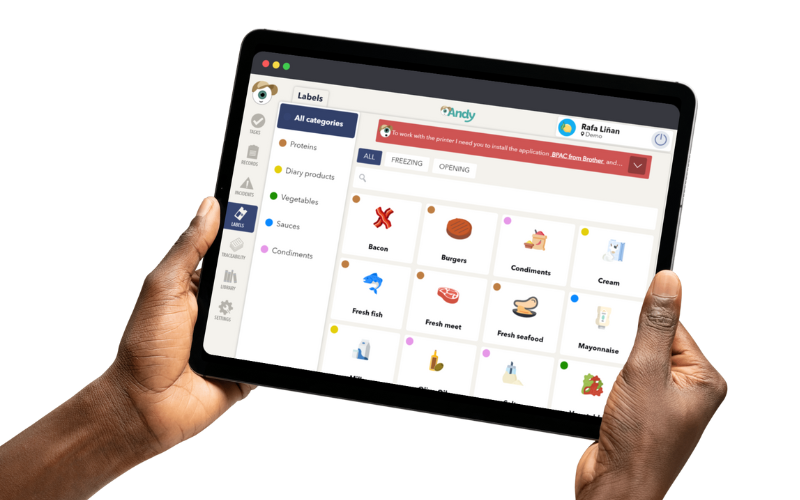

Empower Your Food Service Kitchen for Success in 2025 with Andy

Avoiding operational mistakes is essential to achieving the excellence that all food service operators should aim for in 2025.

Whether it’s standardising recipe execution, improving workflows, maintaining equipment, or fostering sustainability, addressing these challenges head-on can transform your kitchen into a powerhouse of efficiency, safety, and customer satisfaction.

But let’s be honest -correcting these mistakes manually can be time-consuming and prone to errors.

This is where Andy steps in.

Andy is more than just a digital assistant; it’s your ally in streamlining operations, automating repetitive tasks, and optimising processes in your high volume kitchens.

With Andy, you can:

- Automate routine processes, like food safety monitoring, temperature tracking, food safety labelling, and inventory management.

- Optimise workflows to minimise bottlenecks and improve service speed.

- Streamline audits and self-evaluations, ensuring compliance and continuous improvement.

- Track and reduce food waste, integrating sustainability into your daily operations.

- And a lot more!

Andy isn’t just about solving problems -it’s about empowering your team, boosting efficiency, and ensuring that your kitchen runs like a well-oiled machine.

Let Andy help you turn operational challenges into opportunities for growth and success.

Ready to take the first step?

👉🏽Start your journey with Andy today!👈🏽