Scaling Operations: Consistency in Food Service Doesn’t Happen by Accident

In food service, food retail, hotel groups and contract catering, one word appears in every meeting, every audit and every operational playbook: consistency. Everyone wants the same level of quality every day, in every location, with every team. Yet only a small number of organisations manage to achieve it reliably.

There’s a reason for that:

operational consistency doesn’t happen by accident.

It happens by design.

Quality, Operations and Food Safety leaders know this better than anyone. Consistency isn’t the product of intention — it’s the outcome of systems: clear routines, aligned tasks, reliable records, and processes that work the same way across all locations.

When those systems fail or don’t exist, the operation doesn’t scale. It fragments.

This is why scaling operations requires understanding what truly drives consistency.

Why is scaling operations so difficult?

Because quality depends on repetitive tasks performed consistently across teams, shifts and locations. When processes are manual, variability increases. Digital systems reduce friction, standardise routines and make quality predictable — the foundation for scaling operations at speed.

Scaling Operations in Food Service Brands

1. Scaling operations means eliminating variability

In theory, every site should operate the same way.

In practice, each site improvises differently.

Variability appears when:

-

people interpret tasks differently

-

information is scattered across notebooks, chats or emails

-

checklists are unclear or incomplete

-

validations depend on memory

-

standards shift from one shift to the next

-

there is no clear traceability of what was done

When this happens, quality depends on who is working, not how the work is designed.

And that’s the moment the organisation stops scaling.

2. Consistency isn’t rigidity – it’s repeatable clarity

For many teams, “consistency” can sound like more control or tighter supervision.

But in reality, consistency means something much simpler: clarity.

Clarity about:

-

what needs to be done

-

when it must be done

-

how it must be validated

-

what happens if something goes wrong

When these elements are dependable, teams work with ease, not pressure. They execute faster, make fewer mistakes and collaborate more effectively.

Consistency liberates teams — it doesn’t constrain them.

3. Digitalisation turns quality into a system, not an effort

Trying to scale operations with manual processes is like trying to replicate a restaurant concept by copying a handwritten notebook: the result will never be identical.

Digital systems do something that humans simply cannot sustain manually at scale: they create operational reliability.

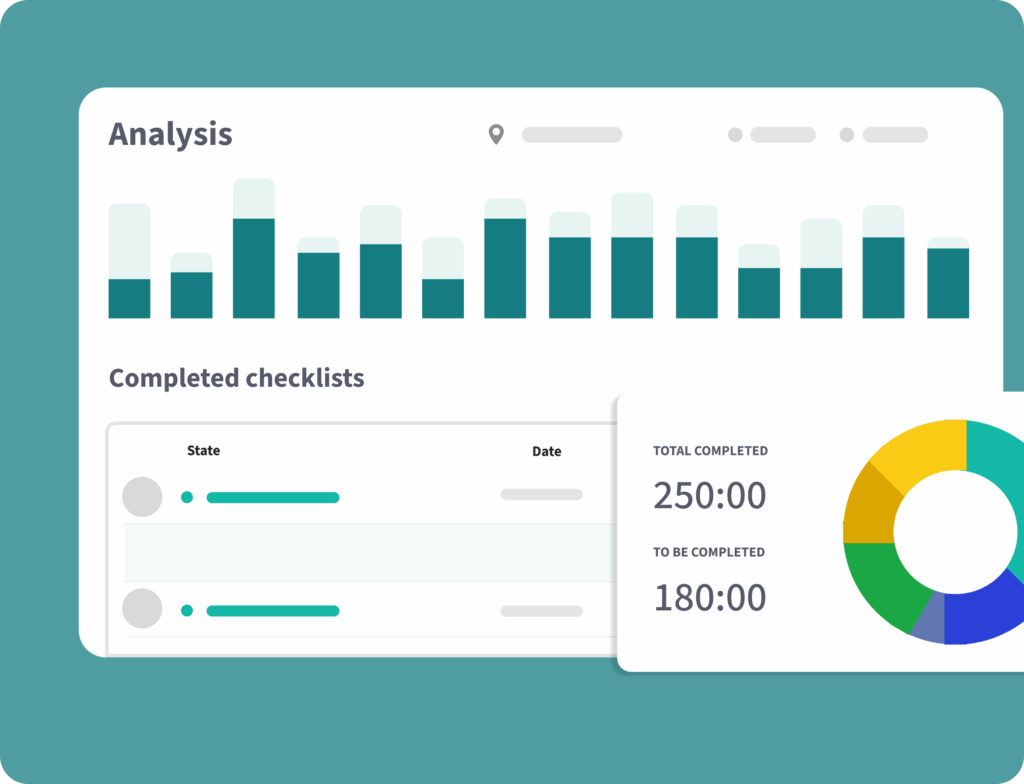

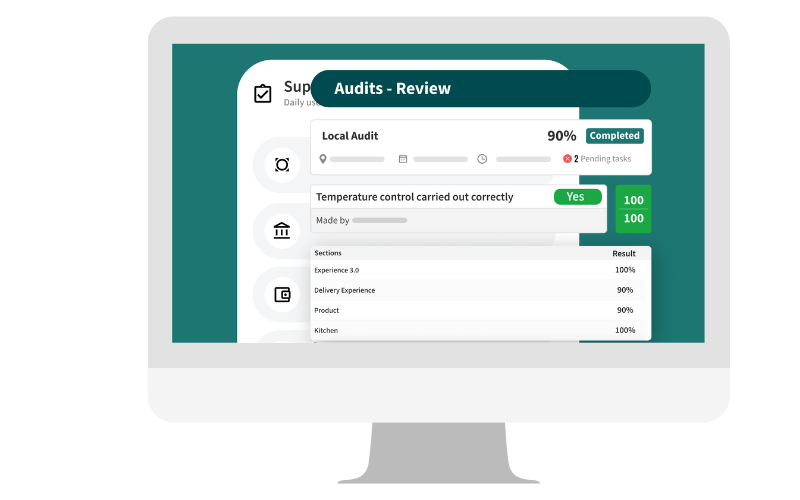

With a digital platform like Andy, operations gain:

-

photo, signature and comment validation

-

automatic alerts for delays or deviations

-

full traceability of actions

-

a centralised dashboard with real-time execution insights

This doesn’t just reduce errors — it builds a repeatable operational pattern, the core requirement for scaling operations across multiple sites.

4. When the system works, teams work

Operational consistency reduces mental load, lowers stress, speeds up openings and closings, strengthens audits and removes duplicated work.

Teams stop firefighting and start performing.

And this is the turning point:

when the system becomes strong, quality stops relying on individual people and starts relying on the process.

That’s what makes scaling possible.

In food service and hospitality, scaling operations doesn’t come from hiring more people, demanding more, or reviewing more checklists.

It comes from designing systems that make the right actions unavoidable.

Because consistency isn’t a coincidence.

It’s a design choice.

It’s a system.

And it’s the foundation of any scalable operation.

When that system is built properly – as it is with Andy – quality stops being a wish and becomes a predictable, measurable and repeatable outcome.